Gate Cutters & Trimmers

Only the Best for the Best… with our advanced blade technology and ergonomic design your customers and employees will SEE and FEEL the difference. Our superior product quality assures long life performance making the DME cutter the ultimate in value

Featuring

Blade Contour

Learn more about matching the Blade Contour to the part at the gate.

Power-Up Gate Cutters

For a “cut above” check out these premium cutters.

Good, Better, Best

Find the right cutter to fit your budget and your need.

Purchase on DME eStore

DME’s Full Range

Good, Better, Best

Selecting the Correct Gate Cutter for Your Application:

To ensure a quality finished product, it is important to choose the proper gate cutter. Consider the following when selecting a cutter:

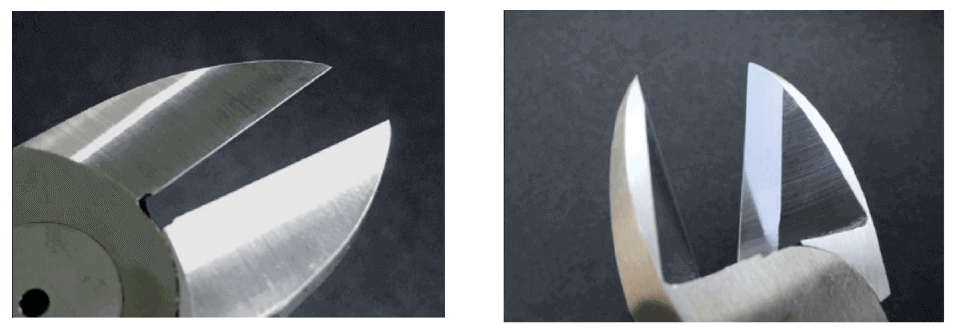

1. Contour of the back of the blade

2. Blade length 3. Blade opening 4. Handle length

The blade characteristics should match the part at the area of de-gating.

Why Cutters Matter

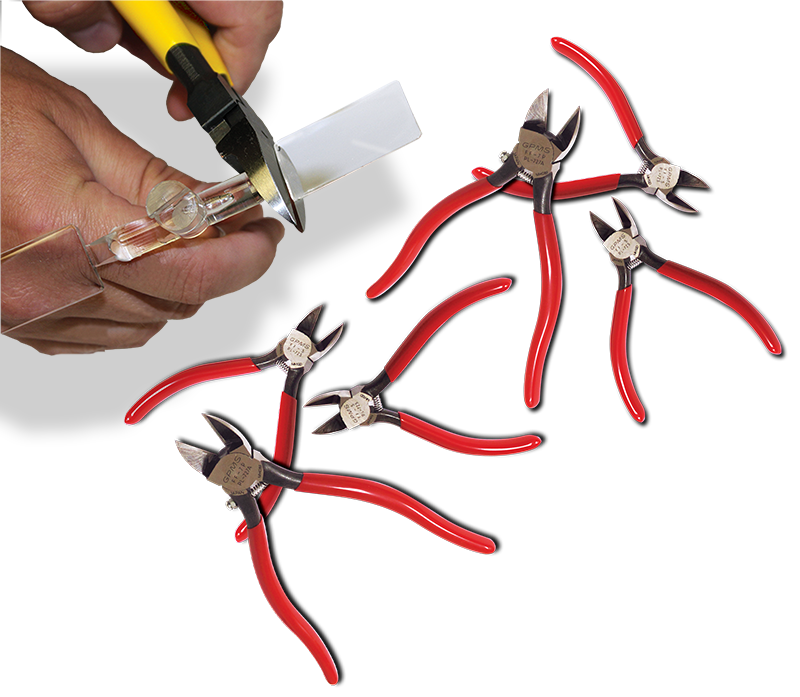

Gate cutters are essential hand tools for injection molders for trimming molded parts free from the gate.

A clean and aesthetically pleasing plastic part relies on a cutter that can provide and consistent a precise cut flush to the molded part and cut cleanly in order to remove the part without damage.

This performance cut must be achieved for every part and over a long period of time.

Because every cut requires the skill and dedication of the operator, the feel and ease of the cut is critical. Right or left handed, the cutter needs to be comfortable and easy for the operator to use for an extended amount of time. All of our cutters offer precision cutting and a user-friendly design. Our handles are ergonomically shaped to fit most hand sizes. The grips are made from a durable, non-slip material. A built-in high quality return spring brings the tool back to the open position again assisting the cutting process.

Our Technology

Design

Our products have been in the hands of our customers for decades and we have relied on their feedback to continually update and advance our products so that today we offer the best cutter available on the market.

Steel Quality Matters

The first step in the manufacture of a high performance cutter is the selection of the steel material. Our premium gate cutters such as our Power-Up line are made using Chrome-Vanadium steel with a unique chemical composition. This steel, only available in Japan, is capable of producing a highly engineered product. This is the same steel type that is used in advanced culinary and medical cutters where precision and long life performance are critical factors.

Precise and Consistent Manufacture

Uniquely crafted and tested through over 50 critical production processes to ensure precise and consistent engineered properties.

The standard of workmanship and materials ensures a longer lifetime performance and delivers a cut that is like no other.

Quality You Can Trust

Every cutter is individually inspected and tested to ensure reliable performance during use.

The result of the process is a product with extreme long lasting sharpness that cut easily through the most demanding materials. Your employees will thank you for this quality tool.

Making the Cut – Compare Cutters

Selecting the right tool for the right job is critical regardless of the industry. Tools like cutters are especially important as they impact the quality of a product and impact the user on a functional level. DME carries cutters that get the job done, exceed the need and cutters that are superior in ergonomic design. Whether you’re only using this tool every few days or every few minutes will determine your needs. Check out our comparison chart below.

Good Cutters

- 5 Sizes to Fit Your Needs

- Flat Face & Nippers Available

- Hardened Steel for Long Life

- Economical

Better Cutters

- Japanese High Carbon Steel Outlasts the Competition

- Precision-ground edge for Easy Clean Cuts

- 7 Different Blade Shapes to Fit Your Application

- 10 Different Lengths of Gate Cutters

- Ergonomic Design

Best Cutters

- Includes All Benefits of “Better” Cutter

- Designed Specifically for Cutting Dense Sprues

- 50% Reduction in Required Hand Force Compared to Conventional Cutters

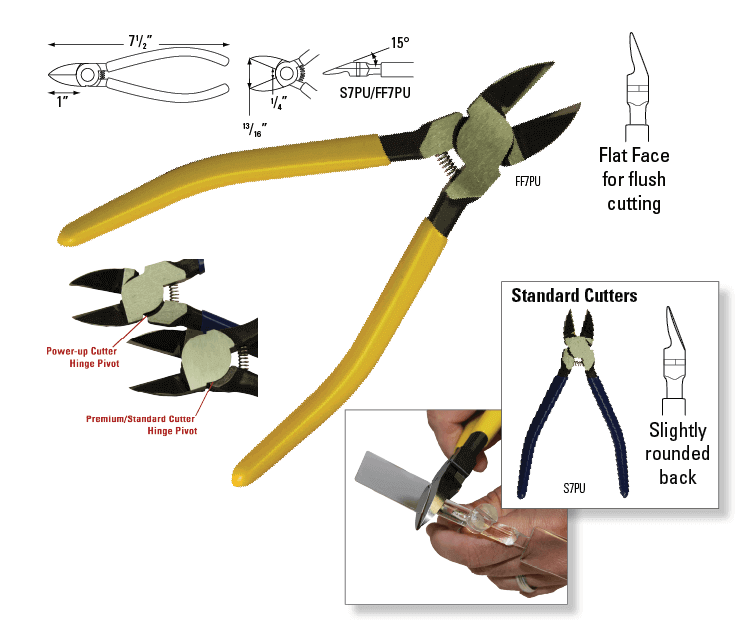

Blade Contour

Flat Face

For general purpose cutting where the sprue is fully accessible or proud of the cutting surface.

Nipper Type (slightly rounded)

For sprue cutting where access to the sprue may be slightly recessed.

Angle Heads

For recessed sprue cutting and access to internal cavities.

Convex/Concave

For special applications where the sprue is recessed.

Blade Stop

When cutting hard or brittle material it is recommended to use a cutter with a blade stop. Adjusting the stop so the blades stop short of hitting each other will extend the life of the blades.

Handles

How much pressure an operator must exert when cutting a sprue or gate is determined by the length of the cutter handle. A handle that is too long for the operator’s hand is difficult to grip while a handle that is too short causes excessive strain. Match the cutter with the operator’s hand and the sprue being cut. Ergonomic handles are an effective way to reduce operator fatigue and decrease the risk of carpal tunnel syndrome. Have a left handed operator? We have left handed gate cutters

Quality Cuts: Power-Up Premium Gate Cutters

The BEST Choice of Cutters – The Power-up Cutters are designed specifically for cutting heavy duty large sprues with reduced hand pressure. The unique design and forging positions the hinge pivot point off-center to create a cam action which increases blade cutting pressure.

Simple mechanical leverage principle reduces the required hand force by up to 50% compared to conventional cutters. The new design of these cutters are ideal for repeat cutting of large, heavy sprues and particularly tough applications such as glass-filled resins.

Quality Cuts: DME Premium Gate Cutters

The Best – Gate Cutters & Trimmers Fit for Every Need.

Features:

- High carbon steel holds its edge and out lasts the competition by 1.5-2 times

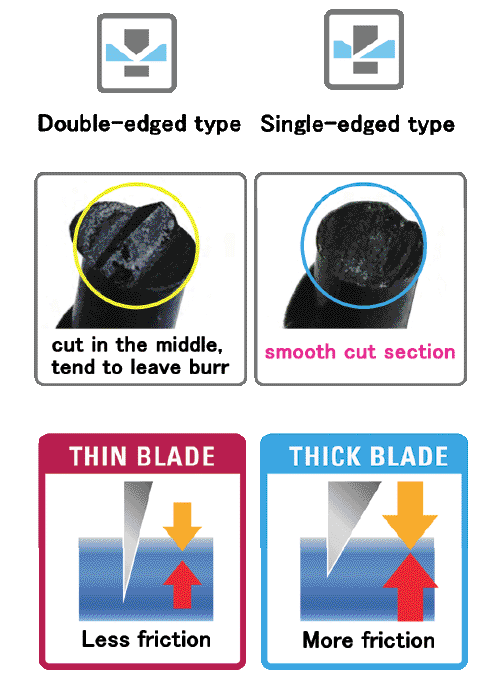

- Electronically hardened and precision ground to 30˚ results in an ultrasharp, low profile cutting edge than the competition’s 60˚ allowing the blade to cut through plastic without pinching or crushing

- 7 blade shapes

- 10 gate cutter lengths

- Ergonomic cutters to reduce stress in the wrist when performing repetitive tasks (right and left handed versions available)

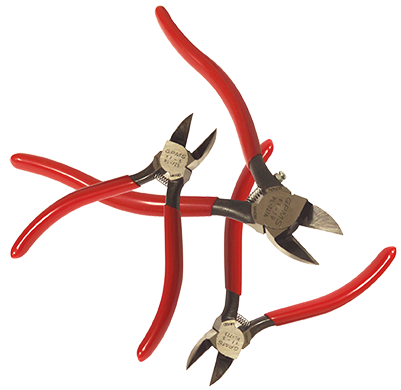

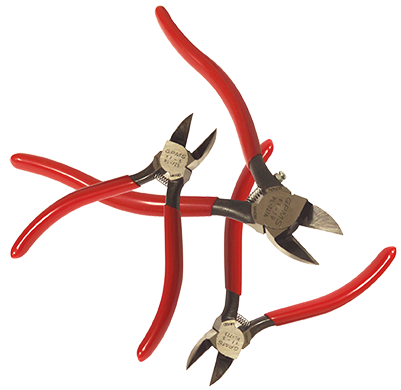

Quality Cuts: Pro Series Gate Cutters & Nippers

A BETTER – HIGH QUALITY & AFFORDABLE CUTTERS & TRIMMERS

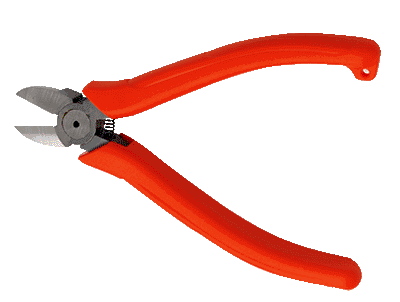

Mini Size Nippers

Mini Size Nippers for small sprue and gate cutting where less force is required. The unique hinge design and off set handles provide a cam action resulting in increased blade cutting pressure with less effort than traditional cutters. The new hinge design, highly polished blades and coil spring pack a 1,2,3 punch allowing for hours of cutting with less fatigue.

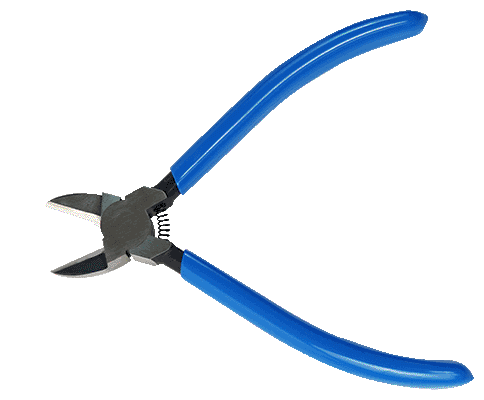

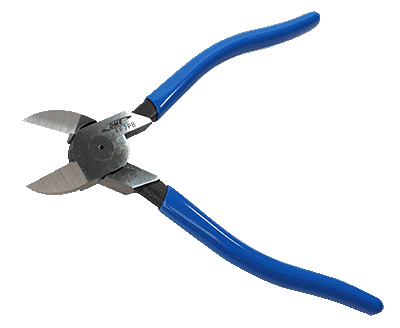

Thin Blade Cutters

Thin Blade Cutters are ideal due to their slicing action through the gate as apposed to a crush and cut which leaves an unattractive edge and requires more hand force. Try a thin blade cutter to see and feel the difference.

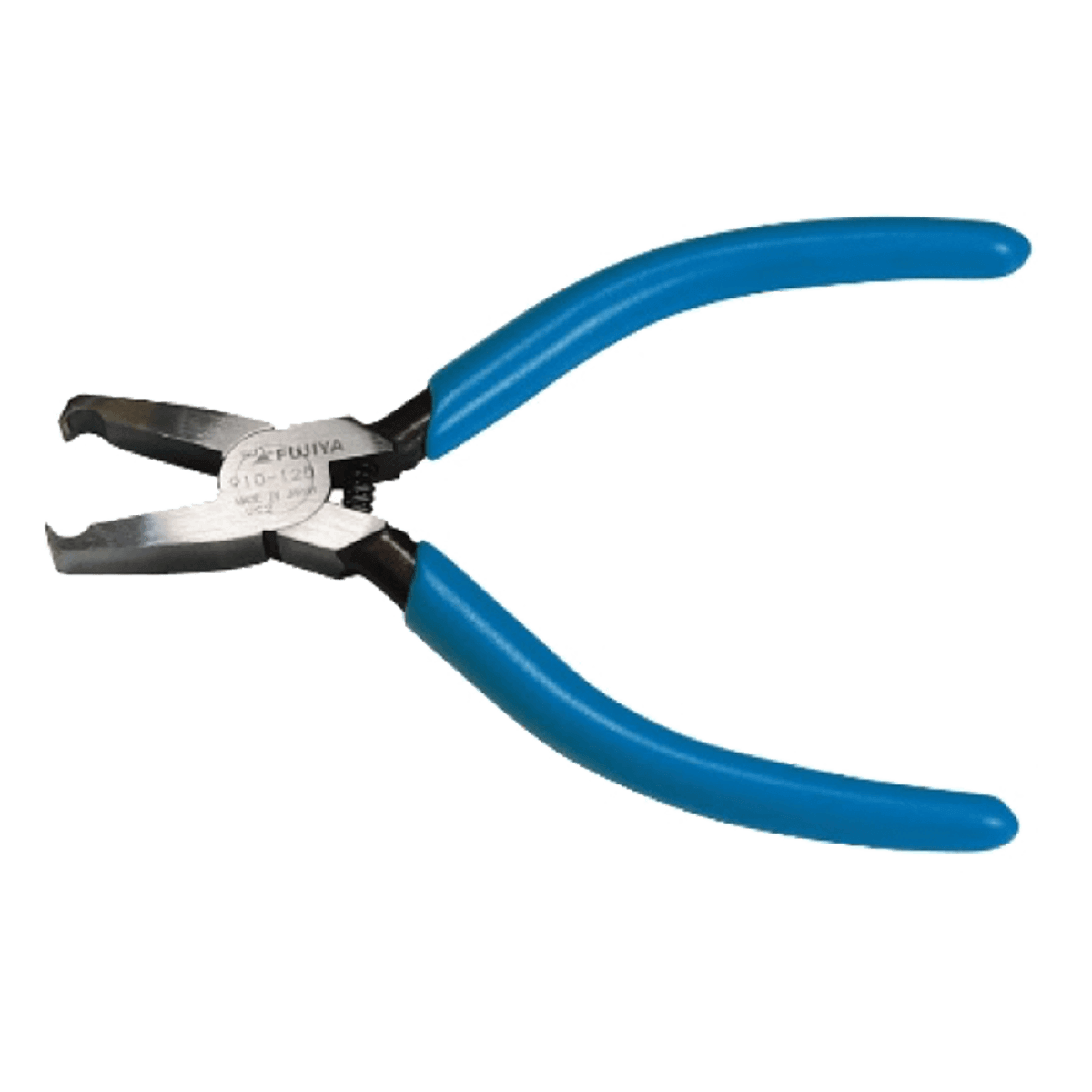

Single Blade Cutters

The Single Blade Cutters are designed for cutting the hard plastic gates of engineered resins (POM, PA, PC, etc.). A single blade enables the user to “slice off” plastic without leaving flash on the cut section for a nice clean edge. The cutters also incorporate a coil spring for easy continuous cutting. Available in Round and Flat Face blades to fit your application.

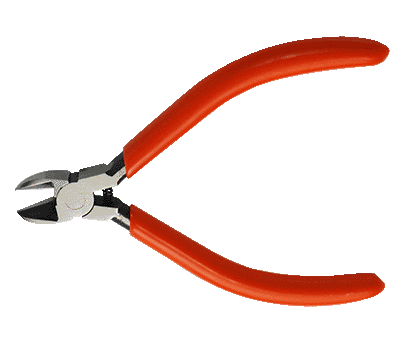

Comfort Grip Cutters

Comfort Grip Cutters feature a combination of comfortable elastomer handles and polished blades to a perfect matched allowing this cutter not only to provide a beautiful cut but to feel great while doing so. The cutters also incorporate a coil spring for easy continuous cutting and are available in 5 and 6 inch overall lengths.

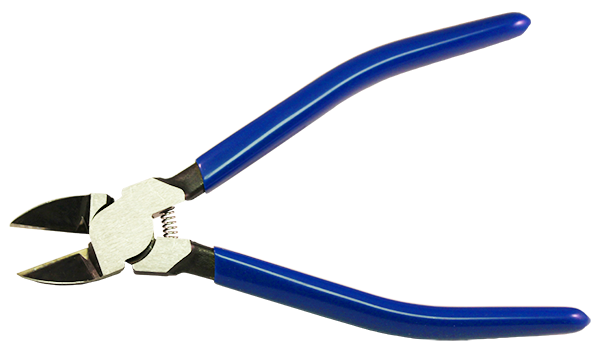

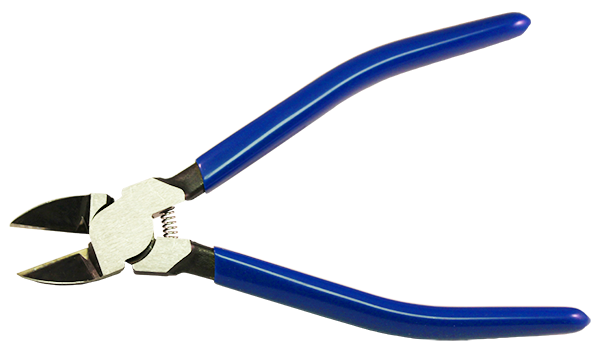

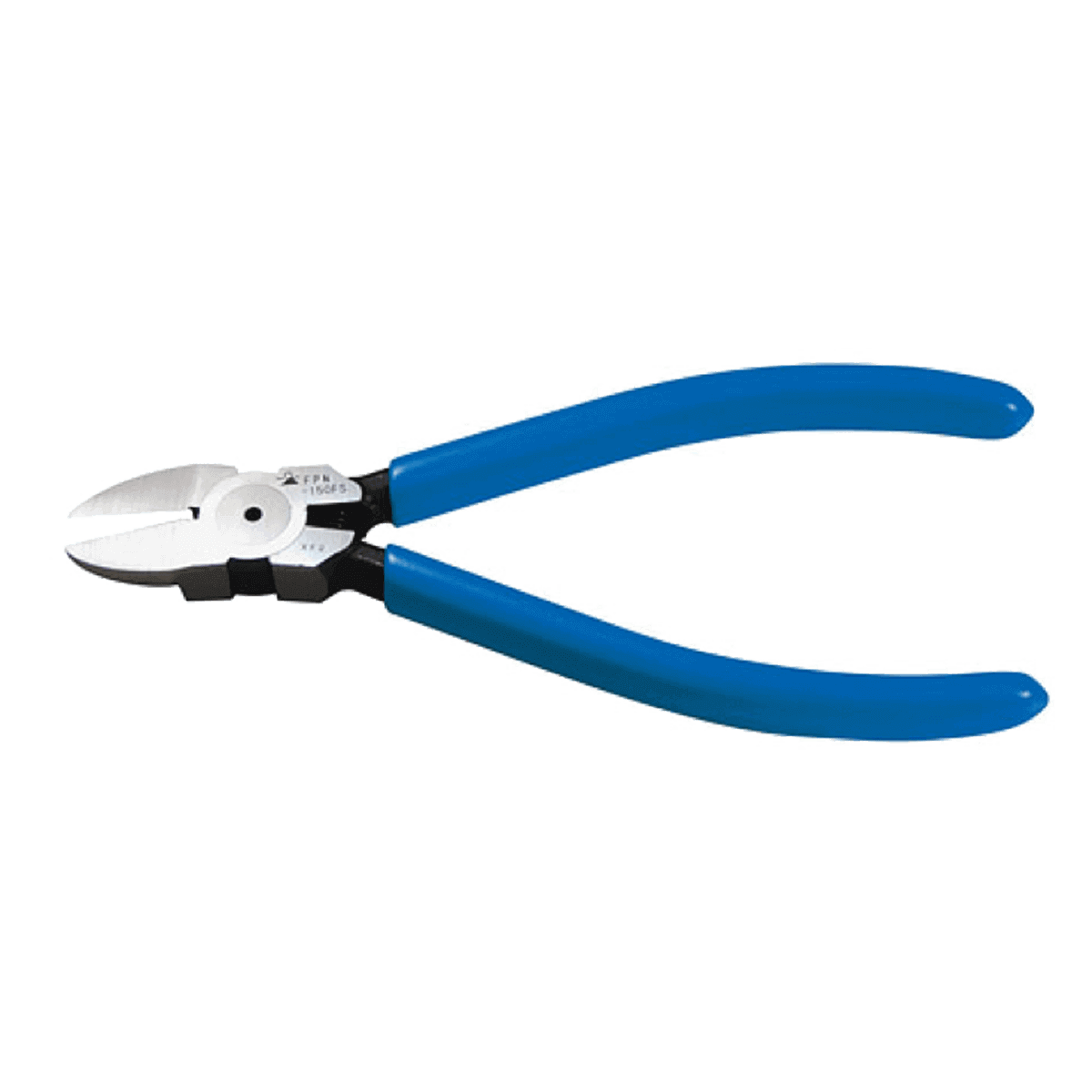

Heavy Duty Cutters

Heavy Duty Cutters are designed specifically for cutting heavy duty large sprues with reduced hand pressure. The unique hinge design and forging positions the pivot point off-center to create a cam action which increases blade cutting pressure. Most suitable for large and glass filled gate cutting associated with injection molded plastic, plastic burrs and plastic model making. Available in 7 and 8 inch overall lengths.

Force Enhancement Cutters

Force Enhancement Cutters are newly designed cutters ideal for repeat cutting of large, heavy sprues and particularly tough applications such as glass-filled resins. The forged high carbon steel blades are ground and polished to achieve very keen edge, resulting in a beautiful cut cross section. Coil springs are incorporated to continuous cutting. Sanitary antibacterial grip handles are applied to prolong use.

End & Angle Cutting Nippers

End and Angle Cutting Nippers for easy cutting of gates no matter the application DME has the cutter for you. End Plastic Cutting Nippers for vertical entry suitable for cutting gates and burrs in recessed areas. Coil springs are incorporated enabling continuous cutting. Sanitary antibacterial grip handles are applied to prolong use.

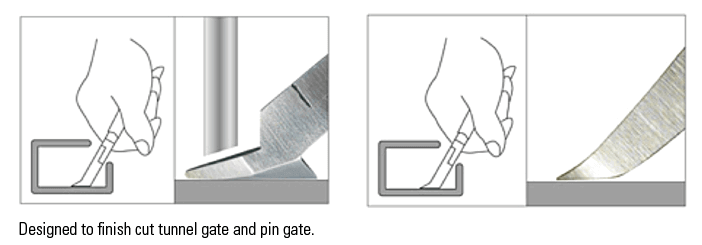

Angled Plastic Cutting Nippers

Angled Plastic Cutting Nippers for vertical entry. Most suitable to finish cut tunnel gate and pin gate areas. Both cutters have rounded blades with sanitary antibacterial grip handles applied to prolong use.

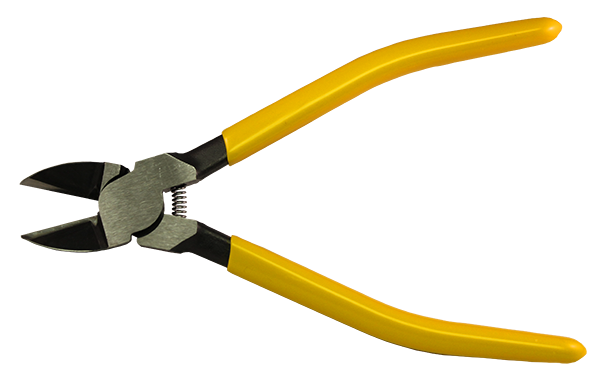

Quality Cuts: DME Standard Gate Cutters

A Good Cut – Gate Cutters & Trimmers Fit for Every Need.

Need a high quality cutter on a budget?

DME’s standard cutters provide high quality results at an economic price point. Offered in a wide range of lengths and blade styles the standard cutter is forged from high quality steel and ground to a sharp cross cut edge for long lasting usage. Have a hard to reach recessed gate? Try one of our specialized cutters designed to make the job easy.

Worldwide:

+1.248.398.6000

USA:

+1.800.626.6653

Canada:

+1.800.387.6600

Mexico:

+52.442.713.5666

Europe:

+32.15.215011

Asia:

+86.775.8601.9031

SUPPORT

Customer Support

Order Support

Documentation

Terms of Sale

Return

FAQ

Credit Application

Hot Runner Service & Repair

Controller Repair & Calibration

ProService (CoolingCare)

Application Engineering

Mold Flow Services

Barrel Repair & Resleeving

Contour Roughing