MELT Delivery Solutions

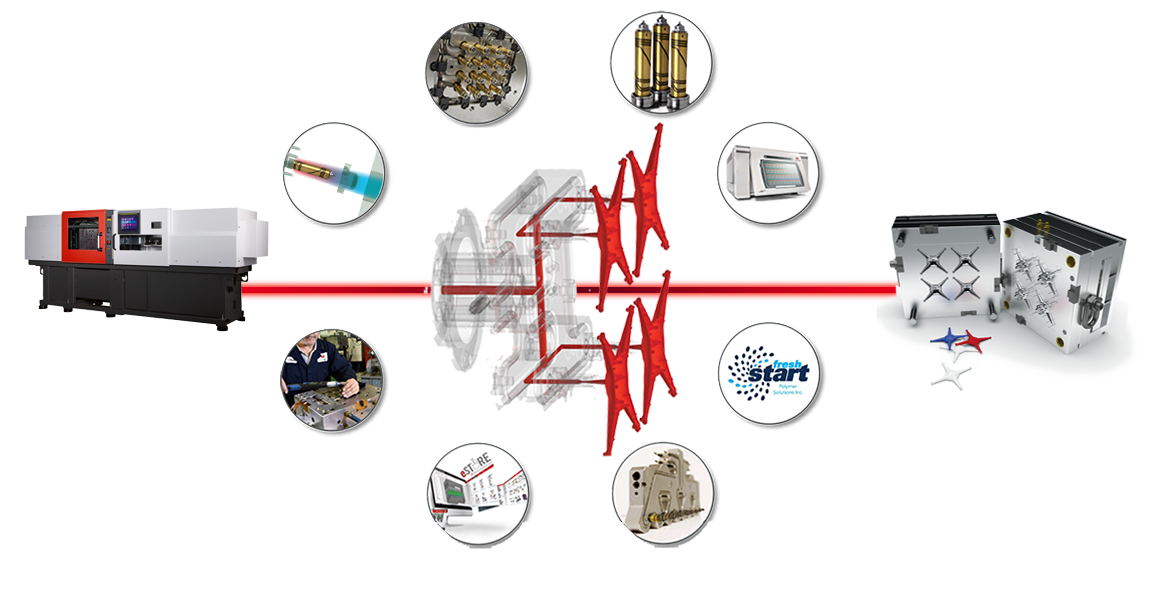

The optimal designed part relies on the melt delivery system feeding it. The DME modular hot runner systems create uniform melt conditions to each gate to allow for pressure limitations, minimizing shear, and excellent cavity packing. The net result is a perfect plastic part produced with reliability and high efficiency.

Featuring

Modular Solutions

Our simple modular designed hot runner products are back with unrivalled service to maximize your manufacturing productivity

Regional Support

All our systems are supported by our field technical engineers and access to the DME eSTORE for immediate availability of replacement part availability.

Global Supply

DME can meet your project requirements worldwide with the standard high quality product range

Integrated Tooling Systems

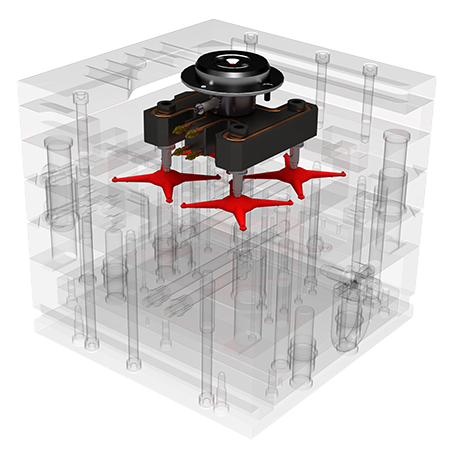

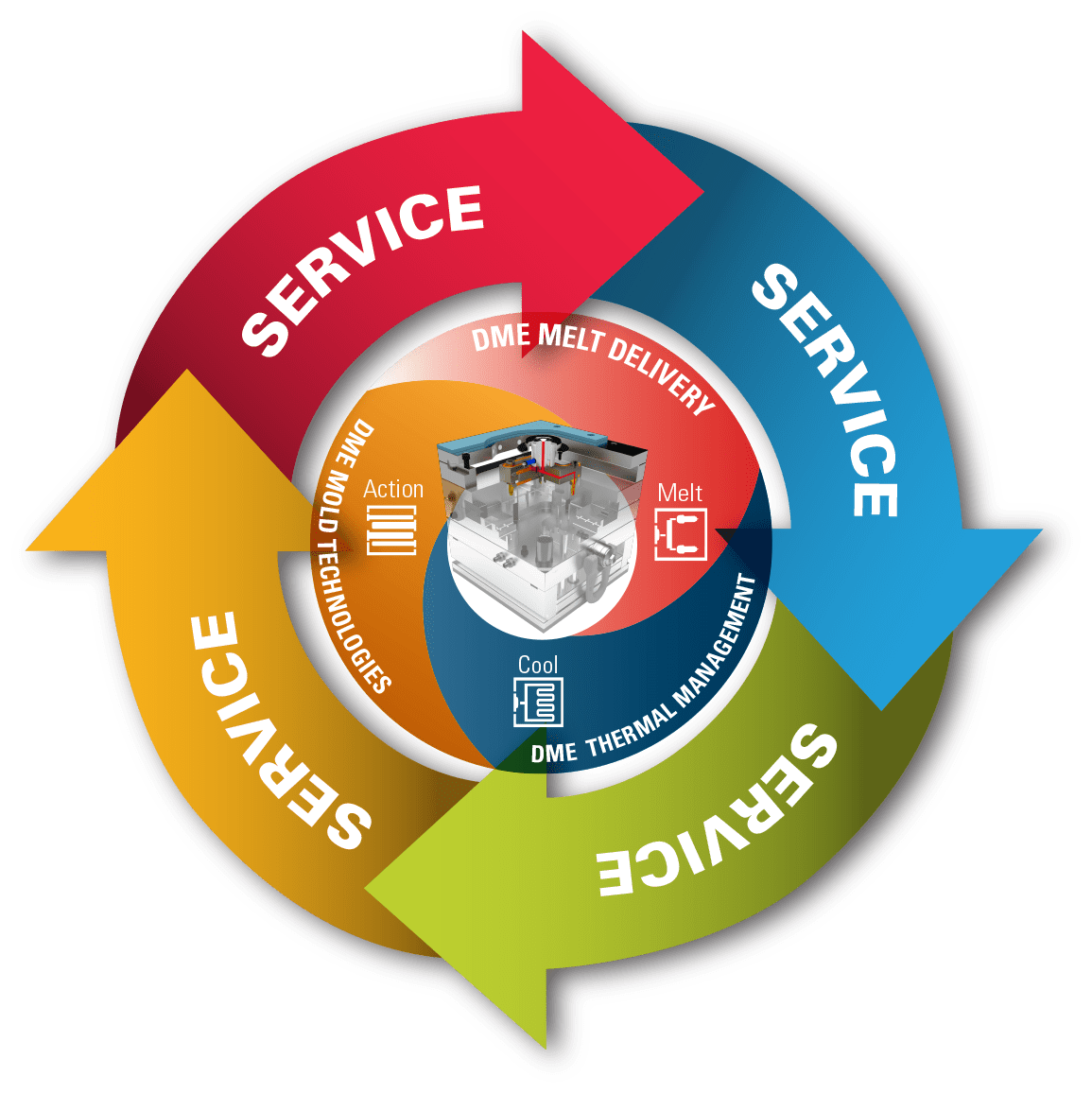

We combine our different technologies to create systems that maximize your output of high quality plastic parts.

For More Information

Melt Delivery Solutions

The quality of a molded plastic part is directly related to the way the mold cavity is filled. A well designed hot runner system builds on the upfront analysis of the part design to determine, the type, number and location of the gate(s). The pressure, temperature and velocity with which a hot runner system delivers the resin into the cavity will produce optimum part quality. The part relies on the melt delivery system feeding it. A superior designed melt delivery system creates uniform melt conditions to each gate to allow for pressure limitations, minimizing shear, and providing for cavity packing. The net result is the perfect product produced with reliability and high efficiency

Your Melt Delivery Partner

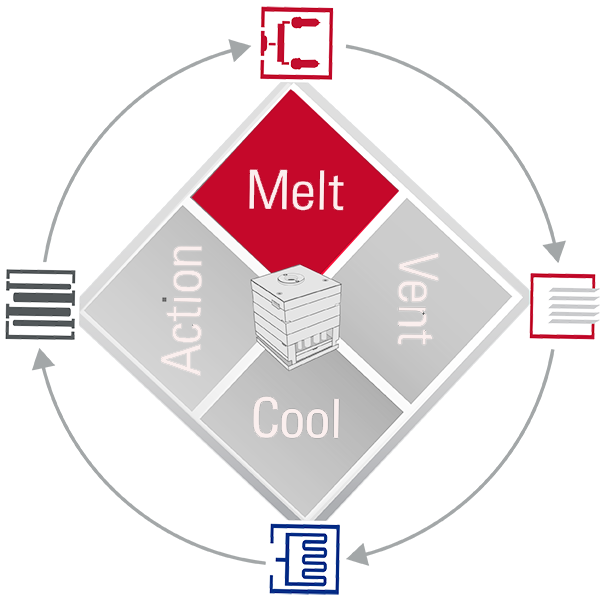

As a world leader in melt delivery we work with you through the entire process.

From understanding the intended application, the resin selected and the process of manufacturing we help you to determine the right system for requirements.

We guide you as to the use of a cold sprue or hot drop. Help you to determine the best gate type and location. Ensure that accurate temperature control along with the melt delivery path are deployed and managed through the necessary hot runner controllers. We help guide the control of the valve gate timing in relation to the injection sequence.

Mold Technologies Package Solution

The DME Melt Systems fit right into the complete package solutions offered by DME. Analysis, Hot Runner, Cooling, Mold Bases & Components, Temperature Control and Molding Supplies.

From start to finish, top to bottom… it can all be included.

Lifecycle Value Solution

DME Melt Solutions are part of the DME complete lifecycle products and services package.

DME understands that you need products and services that support you from the design stage, through development, to execution and service through the life of the project. DME is with you; Every Part… Every Step of the Way.

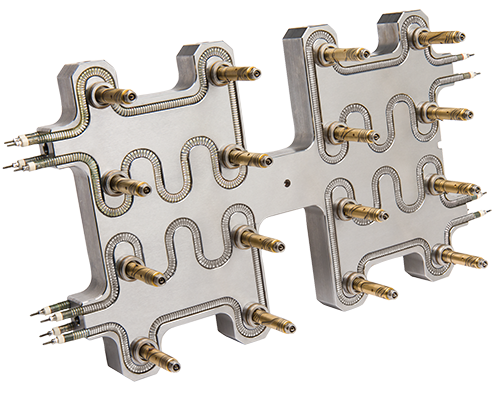

The Problem: Resin delivery is a precision process that often suffers due to inadequate cooling. As resin enters the mold cavity through the gate region, residual heat builds up negatively affecting the mold performance and part quality. Gate blemish such as splay or blush and even warpage often result from this excessive heat buildup at the melt entry point.

Your Melt Delivery Partner

As a world leader in melt delivery we work with you through the entire process.

From understanding the intended application, the resin selected and the process of manufacturing we help you to determine the right system for requirements.

We guide you as to the use of the proper hot sprue bushing or a multi-cavity hot drop system. Help you to determine the best gate type and location, and assist with the best part layout within the mold for optimum flow and balance.

Provide recommendation on the optimal thermocouple sensing locations to ensure accurate temperature control along the melt delivery path using the hot runner temperature controllers.

We help guide the control of the valve gate timing in relation to the injection sequence with the use of dedicated pneumatic or hydraulic control systems, that integrate seamlessly with your DME hot runner valve gate systems.

From pellet to finished molded part, DME provides the assistance you need.

Worldwide:

+1.248.398.6000

USA:

+1.800.626.6653

Canada:

+1.800.387.6600

Mexico:

+52.442.713.5666

Europe:

+32.15.215011

Asia:

+86.775.8601.9031

SUPPORT

Customer Support

Order Support

Documentation

Terms of Sale

Return

FAQ

Services

Hot Runner Service & Repair

ProService (CoolingCare)

Application Engineering

Mold Flow Services

Barrel Repair & Resleeving