American Drill Bushing Lifting Rings

Revolutionizing Hoist Rings and the Lifting Industry by Providing Safe and Innovative Products, On Time

Featuring

Hoist Rings Selection

– Safety Engineered Hoist Rings

– EZ-Torqe Hoist Rings

– Side Pull Hoist Rings

Purchase on DME eStore

Engineered for Safety

At DME safety come first. This philosophy has driven us to offer a collection of Mold Lifting and Rigging hardware that has been certified and proof tested. We stand behind these products and are confident they are the highest quality in the industry. Keep your most valuable assets, your employees and materials safe by using DME lifting hardware.

Hoist Rings

ADB SAFETY Hoist Rings

- Material used: High strength 4140 alloy steel

- Design Factor/Safety Factor: 5:1, Magnetic Particle Inspected Per ASTM E1444, Hoist Rings retain the same rated load from 0 to 90 degrees from the bolt axis, Standard tolerance +- .030 inch unless otherwise specified.

- Finish Coating: Black Oxide Finish for corrosion resistance, Also available in Cadmium, Titanium-Cadmium, Nickel and other plating.

- Approved Range of Movement: Swivel 360°, Pivot 180° Under Load

- 200% Proof Load Tested

- Individually Serial Numbered

- Patent Numbers: 5,848,815

Since 1942 ADB has Provided the Safest Lifting Devices and Hardware Available

ADB is an industry leader in Hoist Rings and offers other lifting solutions for the multiple industries. ADB lifting products are made from high-strength alloy steel. Their ISO 9001:2008 Quality Assurance Program ensures all processes are controlled and implemented per their defined procedures providing the highest level of product quality.

Lifting Rings Made in the USA

ADB’s Safety Engineered product line is 100% manufactured and assembled in the USA. All other product lines consist of a majority of USA manufactured components and are assembled and inspected in their Georgia Manufacturing Facility.STD-209K.

Hoist Rings Selection

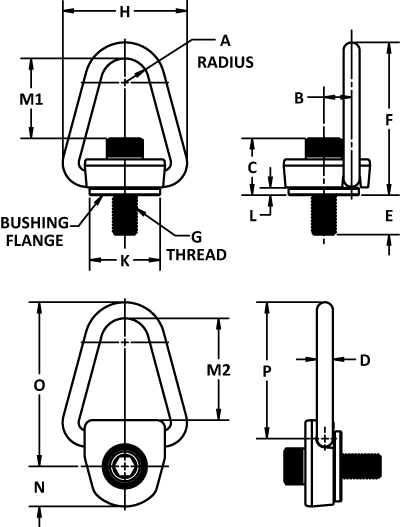

Safety Engineered Hoist Rings

Material: High strength 4140 alloy steel

Design Factor: 5:1, Magnetic Particle Inspected Per ASTM E1444, Hoist Rings retain the same rated load from 0 to 90 degrees from the bolt axis, Standard tolerance +- .030 inch unless otherwise specified.

Finish: Black Oxide Finish for corrosion resistance, Also available in Cadmium, Titanium-Cadmium, Nickel and other plating.

Range of Movement: Swivel 360°, Pivot 180° Under Load

200% Proof Load Tested

Individually Serial Numbered

All dimensions approximate – variations do not effect use or design factor.

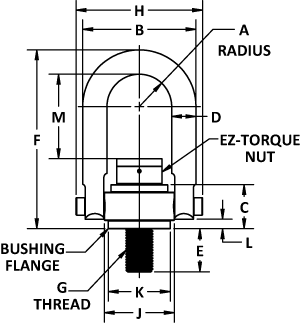

EZ-Torque® Hoist Rings

Material: High strength 4140 alloy steel

Design Factor: 5:1, Magnetic Particle Inspected Per ASTM 1444. Hoist Rings retain the same rated load from 0 to 90 degrees from the bolt axis.

Range of Movement: Swivel 360°, Pivot 180° Under Load

Finish: Black Oxide finish for corrosion resistance*

Typical Applications: ADB, the originator and leader in safety hoist rings, introduces another time and money saving innovation. ADB’s new EZ-Torque® Hoist Ring eliminates the need of locating and installing hydraulic torque multipliers for large hoist ring installations. A 75,000 lb. rated load hoist ring requires the mounting screw to be torqued to 4,300 ft.lbs. Using ADB’s EZ-Torque® Hoist Ring requires only a standard torque wrench and 92 ft.lbs. of torque per bolt!

Patent Numbers: 5,848,815

All dimensions approximate – variations do not effect use or design factor.

* Also available in a wide range of plating – e.g Cadmium, Titanium-Cadmium, Nickel, etc.

Click part number for CAD model.

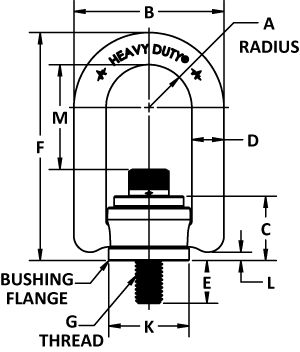

Heavy Duty® Side Pull Hoist Rings

Range of Movement: Rotates 360°

Design Factor: Minimum of 5:1 in any direction, Magnetic Particle Inspected Per ASTM 1444, Unit is supplied in one (1) piece so that parts cannot get lost, Self-aligning in the direction of the load.

Finish: Alloy steel, black oxide finish for corrosion resistance

Patent Numbers: 6,267,422

All dimensions approximate – variations do not effect use or design factor.

Click on part number to see CAD model.