Steel Converting & Machining Services

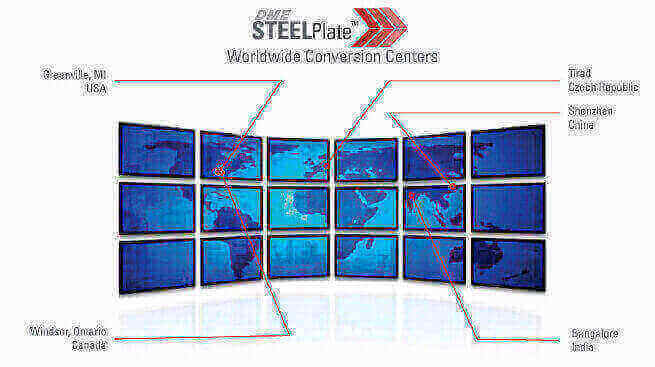

To satisfy the needs of our global client base, DME has established Steel Conversion Centers in five countries on three continents. Whether it’s cutting, drilling or CNC machining steel, DME is ready to support our clients needs, budgets and timelines.

For More Information

Machining Made Easy

3 North American Steel Conversion Centers

With our conveniently located North American Steel Conversion Centers (and many more located worldwide), DME provides its customers with an unmatched range of machining services al delivered with quality, and speed of delivery.

DME offers the best in class manufacturing solutions, including CNC machining, grinding and turning. Our flexible manufacturing services run 24/7, providing you with efficient, cost-effective solutions.

Cutting

- Saw cutting

- Wire EDM

- Flame / Plasma Cutting

- Water Jet Cut

Cutting Steel

At DME our precision steel plate saws have the capability of producing square-cuts within tight tolerances.

- Cut to your size requirements.

- Broader size tolerance to meet all of your needs.

- Available in all 7 DME Steel families.

- Available “Off-The-Shelf” for rapid shipment.

Grinding

- Rotary Grinding

- Finish Grinding

Steel Grinding

To create a flat surface on steel a grinding wheel moves across the planer surface of the steel removing unwanted surface material (a process know as grinding) . Steel can require surface grinding for various reasons, some of which may include:

- Quicker surface material removal

- Flat planer surface is required

- Precise thickness tolerances are needed

- Surface requires a smooth finish

- There is a need to remove material from very hard materials

Grinding is well suited for any part that requires a close tolerance.

Milling

- Rough Pockets

- Finished Pockets

– TOLERANCES:

– Standard ±0.001”

– High tolerance of ±0.0002” - Rough Tapered Pockets

- Finish Tapered Pockets

- Insert Pockets

- Heel Block Pockets

- Slide Pockets

- Spring Pockets

- Lock Pockets

- Runner Pockets

- Parting Line Relief

- Hot Half Pockets

- Hot Runner Manifolds

Slots

- Slots

- Clamp Slots

- Pry Bar Slots

- Wire Slots

Round Pockets / Bores

- Rough Bore Holes

- Finish Bore Holes

- Leader Pin Holes

- Bushing Holes

- Nozzle Bore

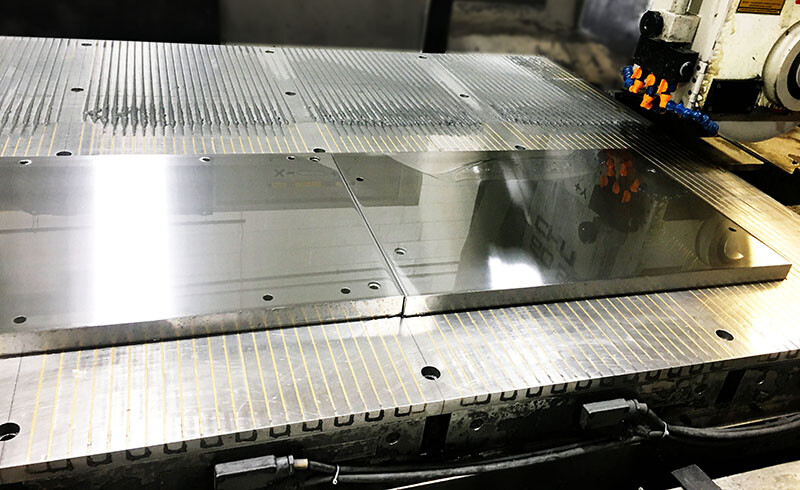

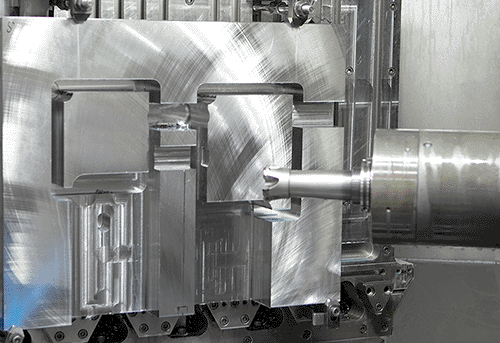

CNC Machining Steel Plate

DME Steel conversion facilities are equipped to handle a wide range of custom steel plates, from small plates used in precision part manufacture to large plates for automotive or caps & closures tools. We offer the highest standard in reliability with highly experienced machinists.

With our decades of experience continually being passed down to the new workers through cross training and apprenticeship opportunities, we fuse modern ideas and energy with time tested, wisdom filled methods and traditions to ensure our workmanship is extremely high quality while still being modern.

CNC Machining

Computer Numerical Control machining, or CNC machining, uses computers to control lathes, mills, routers and grinders.

CNC Machining Has Made Manual Machining Obsolete

Here Are A Few Examples Of How:

- Computer precision makes cuts and adjustments smaller than the human eye can perceive.

- CNC Machining takes place at a speed that can’t be matched by manual NC Machining.

- CNC programing allows models to be identical and done in the exact same movement every time.

- Jobs / Cuts That Would Be Impossible for a human are done effortlessly by a CNC Machine!

Drilling

- Waterlines (Gun Drill)

- Return Pins

- Return Pin Spring Holes

- Guided Ejection

- Ejector Pin

- Angle Pins

- Stripper Bolts

- Bolt Holes (Drill, C’Bore, tapping)

- Eye bolt/Lift Holes

- Spring Pocket Clearance

Drilling Steel Plate

Drilling a steel plate is a simple process where a drill bit, an extremely tough small metal cutting device with multiple points, quickly rotates thousands of time each minute with tremendous force. This drill bit is pressed against a steel plate in a cold cutting process that causes the metal to be pulled out by the rotating drill bit boring a small circular hole into the plate.

The process also removes the shards of steel that once occupied the area that the drill bit passed through. Typically, this leaves a sharpened edge on the side that was entered.

Deep Hole Drilling

Deep hole drilling occurs when machining a drilled hole with a depth to diameter ratio of more than 10 to one. This process is a necessity for a wide variety of manufacturing industries. A few examples include:

- Aerospace

- Automotive

- Gas Mining & Manufacturing

- Heavy Industries

- Medical

- Mold Maker Manufacturing

- Oil Mining & Manufacturing

- Many More!

Deep hole drilling uses a series of special processes including, Gun Drilling, BTA Drilling, Ejector Drilling & even custom processes engineered specifically to each project. These custom processes meet the appropriate tolerance limits while simultaneously surpassing both precision and accuracy goals.

Gun drills are a special kind of drill known for having a straight flute which injects fuel through its hollowed body to its cutting edge. A typical hole depth with a gun drilled machine center should be less than a 50-1 ratio, however, this process can yield a depth to diameter ratio of 300 to 1. At DME we use dedicated gun drills to ensure the highest quality possible.