Krytox™

Grease & Thread Sealant

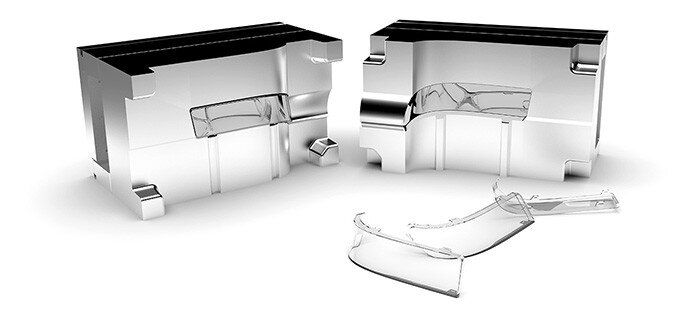

Specifically designed for the lubrication of molds, both electrically and steam-heated. This lubricant sets a new standard in mold and high temp lubrication applications.

Benefits:

Will not bleed to parting line.

More cycles, less maintenance

Extends life of high wear components

Purchase on DME eStore

Only the Best for the Best

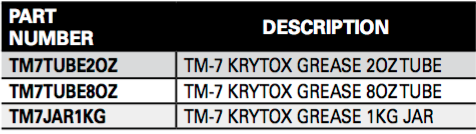

KRYTOX™ TM7 Grease

Chemour Performance Lubricants Extreme conditions. Extreme performance.

The “Stay-Put” Lubricant

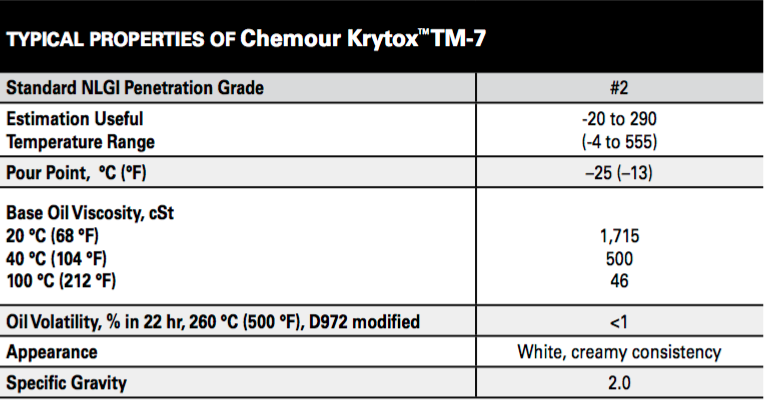

Chemour KrytoxTM TM-7 grease is specifically designed for the lubrication of segmented molds, both electrically and steam-heated. This lubricant eliminates carbon residue buildup on the molds associated with hydrocarbon and hydrocarbon-based synthetic greases. It exhibits excellent adhesion and will not bleed out to the parting line due to high heat tolerance, allowing the operator to significantly increase production by extending lubrication intervals.

KrytoxTM TM-7 is a fluorinated grease with polytetrafluorethylene (PTFE) thickeners and selected additives. It has excellent thermal stability and load-carrying abilities. TM-7 has a high degree of chemical inertness and extremely high hydrolytic stability. Contact with boiling water or steam has no effect on this product, it will stay in the location it was applied, providing the best lubrication possible.

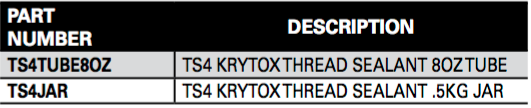

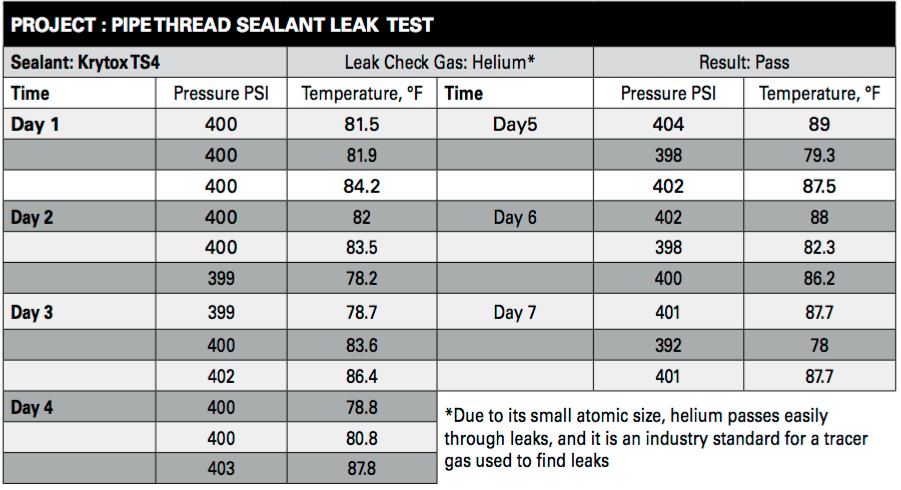

KRYTOX™ TS4 Thread Sealant

Chemour Performance Lubricants Extreme conditions. Extreme performance.

KrytoxTM TS4 thread sealant, the solution for demanding applications, is designed for use on a variety of metal and plastic surfaces.

Specialty formulated for added sealing power, TS4 seals water, air, steam, natural gas and reactive gasses and liquid.

- Can be re-applied over existing Krytox sealant.

- Clings to threads, will not shred or tear on assembly/disassembly

- Cannot plug or restrict critical piping, valves or instruments like tape solids

- Non-reactive, non-toxic, nonflammable, non-corrosive and compatible with most seal, O-ring and valve polymers

- Operating temperature range of -54 to 149°C (-65 to 300°F)

- Can be used in contact with Ethylene Glycol and many other chemicals