Mold Bases &

Plates

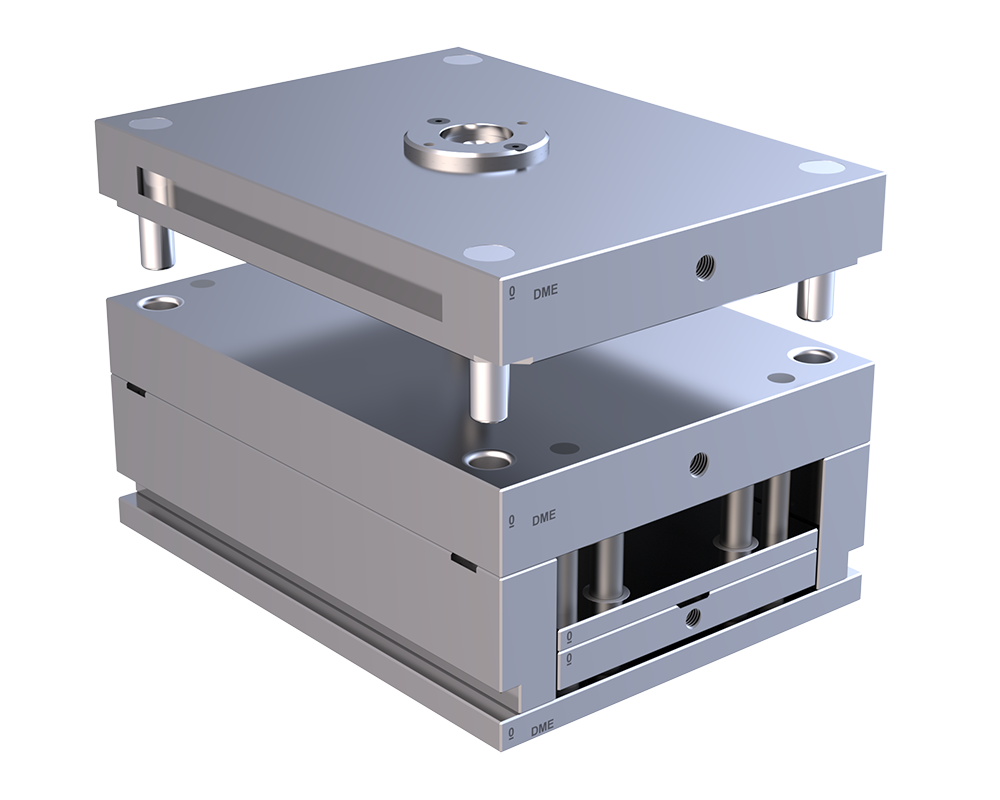

DME Created the mold base standard. 80 years later, DME thrives on providing our innovative components to mold makers worldwide to support their product needs.

Benefits For

Designer

Optimize your design taking advantage of DME standard and engineering products to meet your customer’s requirements for the vest cost/performance molding solution.

Mold & Die Makers

Benefit from DME standard products and gain Speed, Quality and Value as you focus on your higher value core and cavity work.

Molders

Increases the number of quality parts by specifying DME products for each of your tooling packages.

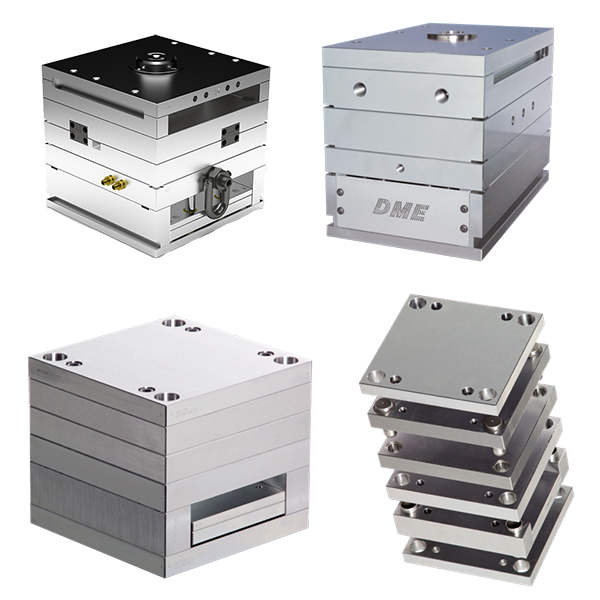

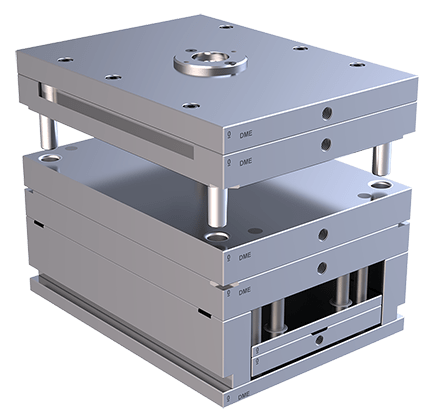

Machined For Quality

DME mold bases and plates are manufactured with the highest quality materials on the most advanced, precision equipment in the industry. Pre-engineered assemblies, plates and components provide the economic and technical benefits of interchangeability. Greater metallurgical consistency and more cleanliness in cavity steels mean more reliability for customers.

Mold Bases Series:

A-Series B-Series

T-Series AX-Series X-Series

Master Unit Die (MUD)

“DME stepped up to the plate to handle an issue created by a freight carrier. What DME did for us was huge. There are always very good lines of communication between us and DME.

It’s definitely a partnership.”

Steve Newell

Tooling Room Manager

Star Headlight & Lantern Co., Inc.

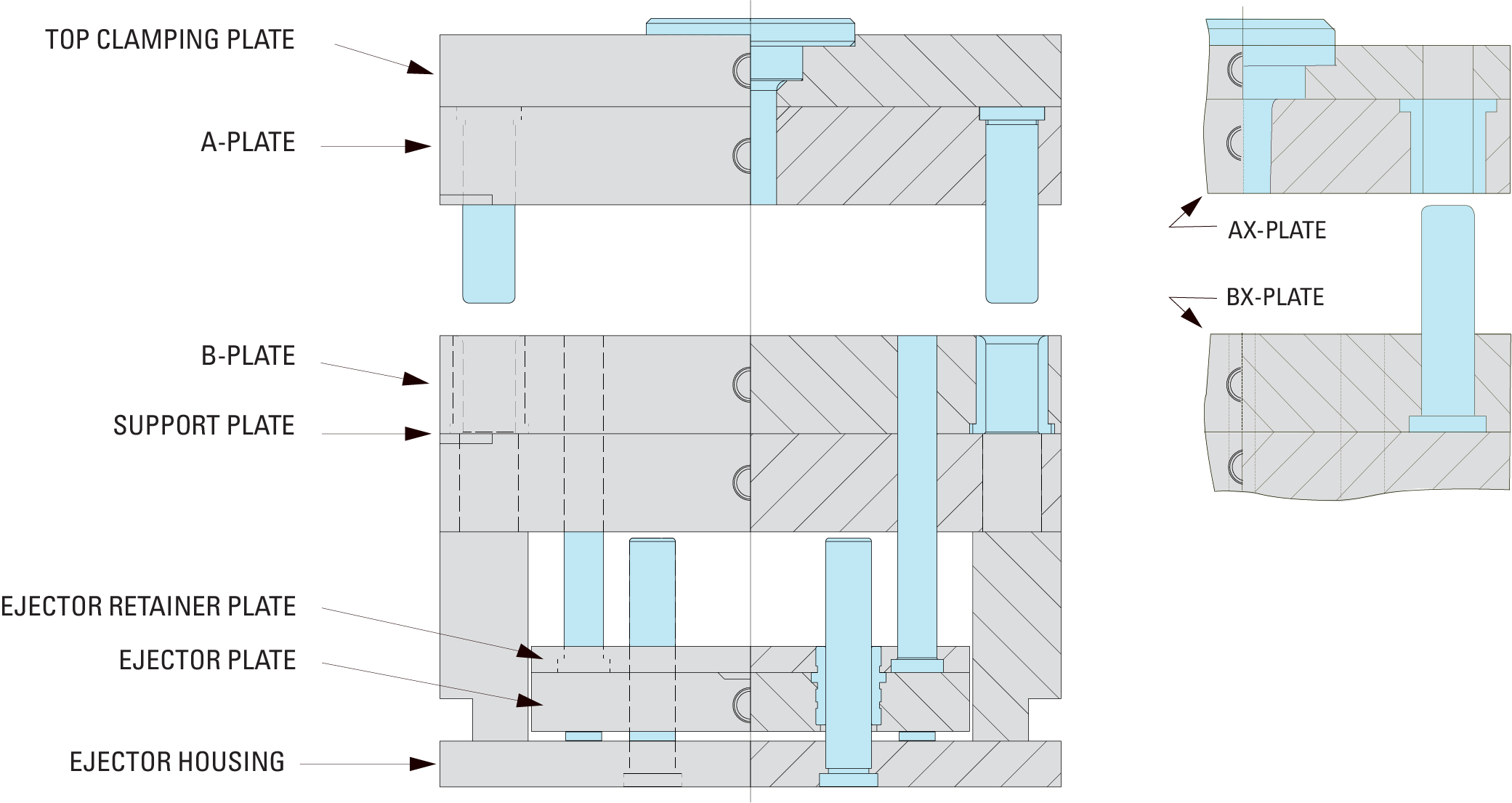

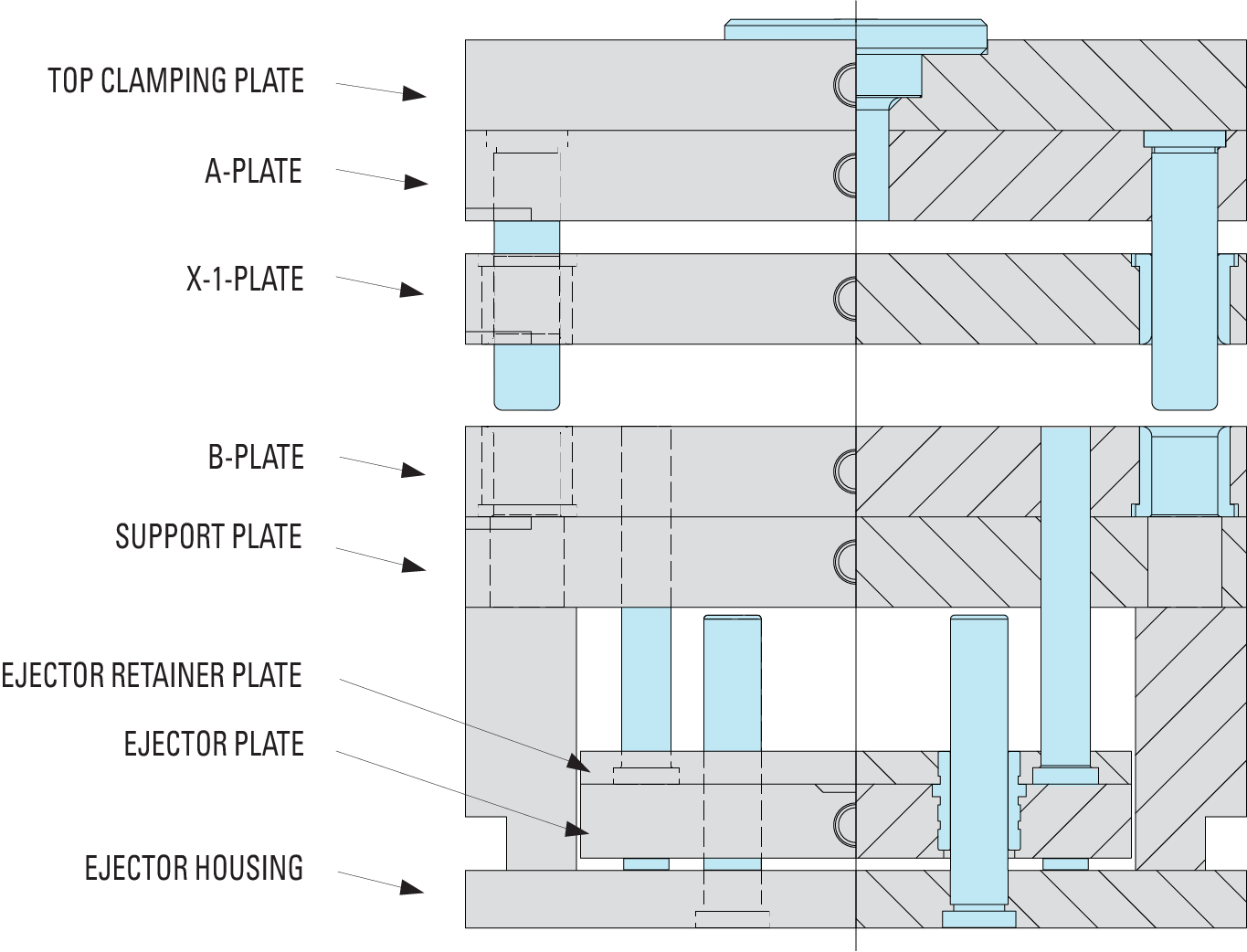

A-Series

DME’s A-Series, 7 plate Mold Base is the worlds most frequently ordered standard assembly.

The A-Series Mold base is available in sizes from 7.875 x 7.875 to 23.75 x 35.5. There are over 75 trillion possible mold base configurations.

- Other sizes can be ordered as a special

- High-quality and reliable tolerances mean more time for mold and die makers to concentrate on cavities and cores – thus increasing productivity as much as 40%

- Like all our products, DME’s Mold Bases come with your satisfaction 100% guaranteed

Features & Benefits

- 7 Plate Stack-up includes Top Clamp Plate, A-Plate, B-Plate, Support Plate, Ejector Bar, Ejector Retainer Plate and a 3-piece housing

- 9 Plate Thicknesses 7/8″ to 5-7/8″

- No.1, No.3, No.7 steel types

- Allows for components to be added, relocated or omitted per your specifications

Specifications

- Production-proven construction that outlasts the longest runs, gives molders more quality parts per hour & more profitability

- Made of high quality, pre-finished mold and die steels that give you more for your money including: metallurgical consistency, more cleanliness in cavity steels, and more reliability

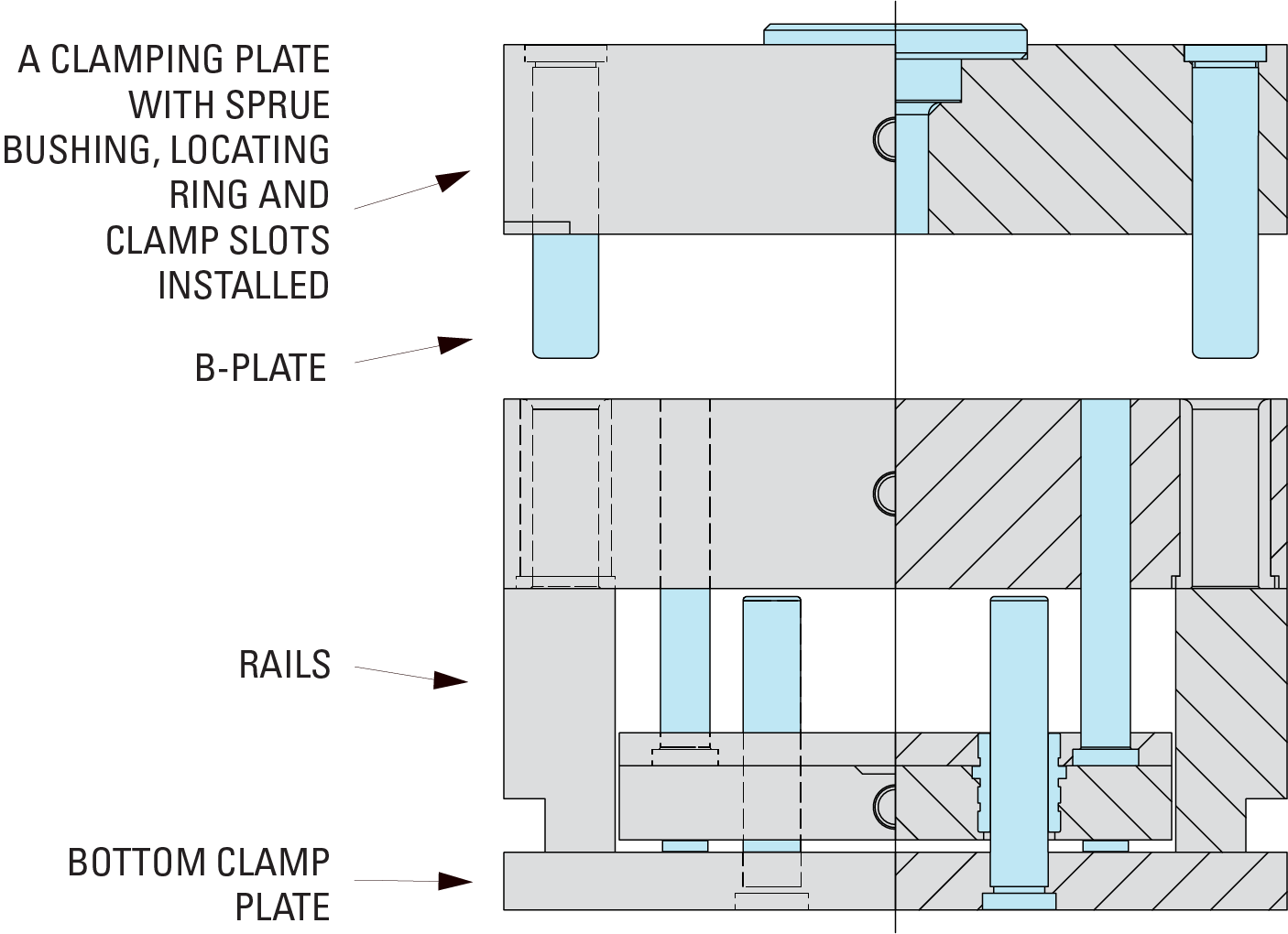

B-Series

DME’s B-Series Mold Bases are a 5 plate design for molds where cavity and core are machined directly into cavity plates.

- B-Series mold bases represents an economy version of the A-Series without sacrificing any quality

- The design combines the top clamp plate and the A-plate into the A-Clamping plate. Likewise, a beefed-up B-plate eliminates the need for a support plate on the core side of the mold

- Available in sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application

- Other sizes can be ordered as a special

- Typically called an “open & shut” tool, there is only one parting line where the runner and part(s) are ejected. The cores and cavities are typically inserted into the A and B plates

- Like all our products, DME’s American B-Series mold bases come with your satisfaction 100% guaranteed

Features & Benefits

- 5-plate Stack-up includes: A Clamping Plate, B-plate, Support Plate, Ejector Bar, Ejector Retainer Plate and a 3-piece housing.

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.3, No.7 steel types.

- Allows for components to be added, relocated or omited per your specifications.

Specifications

- Made of high quality, pre-finished mold and die steels that give you more for your money including: metallurgical consistency, more cleanliness in cavity steels, and more reliability.

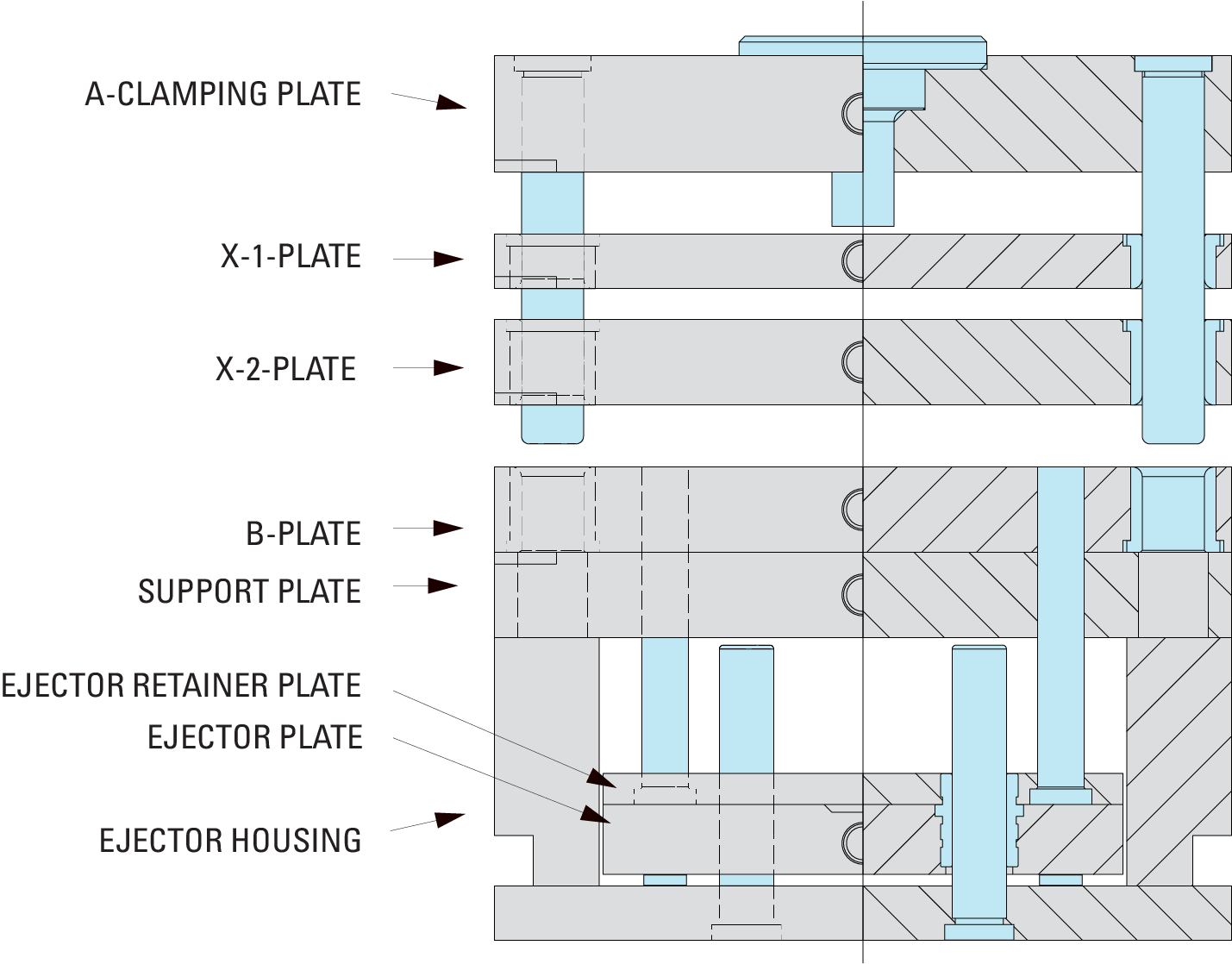

T-Series Mold Base

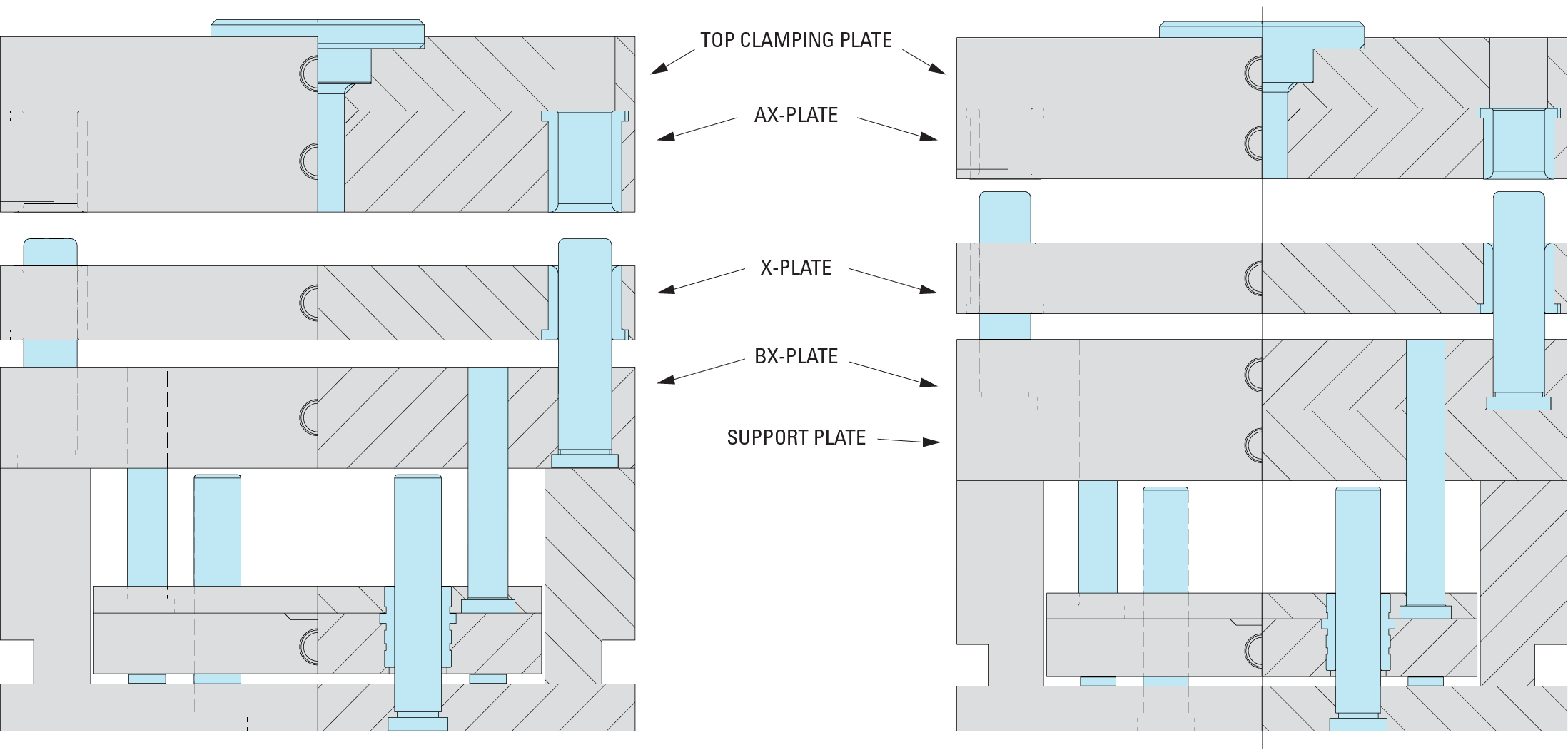

DME’s 2.0 T-Series Mold Base, is used for top runner molds that require two floating plates.

- T-Series, or three-plate, mold bases are used for molds that require separation of the part from the runner in the tool.

- T-Series mold bases consist of an A-clamping plate, X-1 plate, X-2 plate, B-plate, and the ejector assembly and housing.

- T-Series mold bases for top runner molds that require two floating plates (X1 runner stripper plate & X2 cavity plate) to remain with stationary half of the assembly.

- The T-Series operates with two parting lines. The first parting line, which occurs between the X-1 and X-2 plates, separates the part from the gate prior to opening the main parting line. The main parting line then opens and the part is free for ejection.

- Available in sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application. Other sizes can be ordered as a special.

Features & Benefits

- Automatic Degating – in auto mode.

- Separates runner and part.

- Allows central gating – for uniform fill.

Specifications

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.3, No.7 steel types.

- Machining for Type A, B, C or D Clamp Slots.

- Omission of machining for any component for free.

AX-Series Mold Base

DME’s 2.0 AX-Series Mold Base, is the same as the classic A-Series but with an added floater plate.

- An AX-Series mold base is used for parts requiring core detail in the cavity side of the mold.

- When the mold opens, that core detail is pulled so that the part remains on the ejector side of the mold. The AX-Series is essentially an A-series mold base with an “-1 plate, located between the A and B-plates but attached to the top half of the mold so that it can pull the part off the core detail.

- Available in 43 nominal sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application. Other sizes can be ordered as a special.

- Like all our products, DME’s AX-Series Mold Bases come with your satisfaction 100% guaranteed.

Features & Benefits

- Production-proven construction that outlasts the longest runs, gives molders more quality parts per hour & more profitability.

- Made of high quality, pre-finished mold and die steels that give you more for your money including: metallurgical consistency, more cleanliness in cavity steels, and more reliability.

Specifications

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.3, No.7 steel types.

X-Series Mold Base

(5 & 6 Plate)

DME’s X-Series Mold Base is our stripper series with floater plates and reversed leader pins/bushings.

- X -Series, or stripper-plate, mold base sandwiches its stripper (X) plate between the A and B plates and it engages the edge of a part and pushes it off the core.

- The X-Series assembly is available with a support plate (6-plate series) or without a support plate (5-plate series). Typically, the X-Series is used with round parts like cups, caps, and containers.

- Available in 43 nominal sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application. Other sizes can be ordered as a special.

- From a name you trust – DME. Like all our products, DME’s American X-Series Mold Bases come with your satisfaction 100% guaranteed.

Features & Benefits

- Has two parting lines – one which allows the runners to de-mold and the other to allow for part removal.

- Automatic Degating – in auto mode.

- Separates runner and part.

- Allows central gating – for uniform fill.

Specifications

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.3, No.7 steel types.

X-Series 5 & 6-Plate