DME Cooled Sprue Bushings

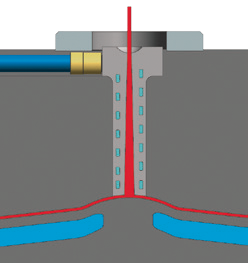

Increase mold output by reducing cycle time and run your mold in a lower cost press by reducing pressures needed to fill your part.

Benefits

Reduce Cycle Time

Reduce long cycle times through superior cooling of the thick sprue.

Lower Pressures

Lower the pressure needed to fill your cavity by adjusting the sprue diameter.

Press Flexibility

Shortening cycle and reducing pressure provide greater flexibility in press selection.

Download Information

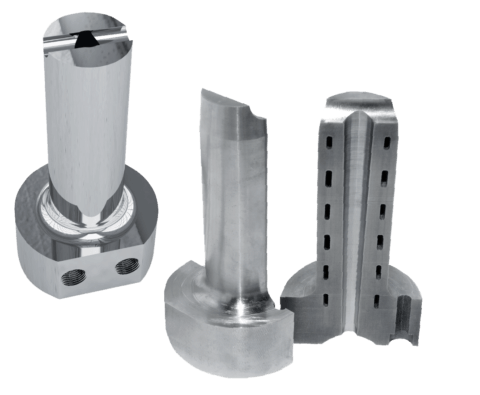

DME Cooled

Sprue Bushings

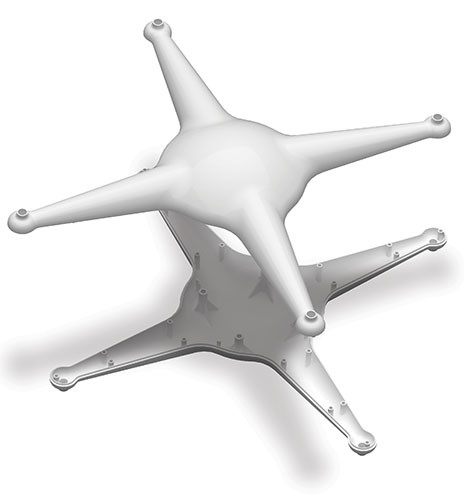

Opening up a wide range of possibilities for the processing of resins in the injection process the DME Conformal Cooled Bushing allows the use of a larger sprue diameter helping to reduce the pressure required to fill your part. The benefits to molding operations are significant and include:

-

Ability to operate on a smaller, more economical press

-

Faster output

-

Lower scrap

-

Consistent quality

DME’s Conformal Sprue Bushing, deliver substantial returns with minimal investment.

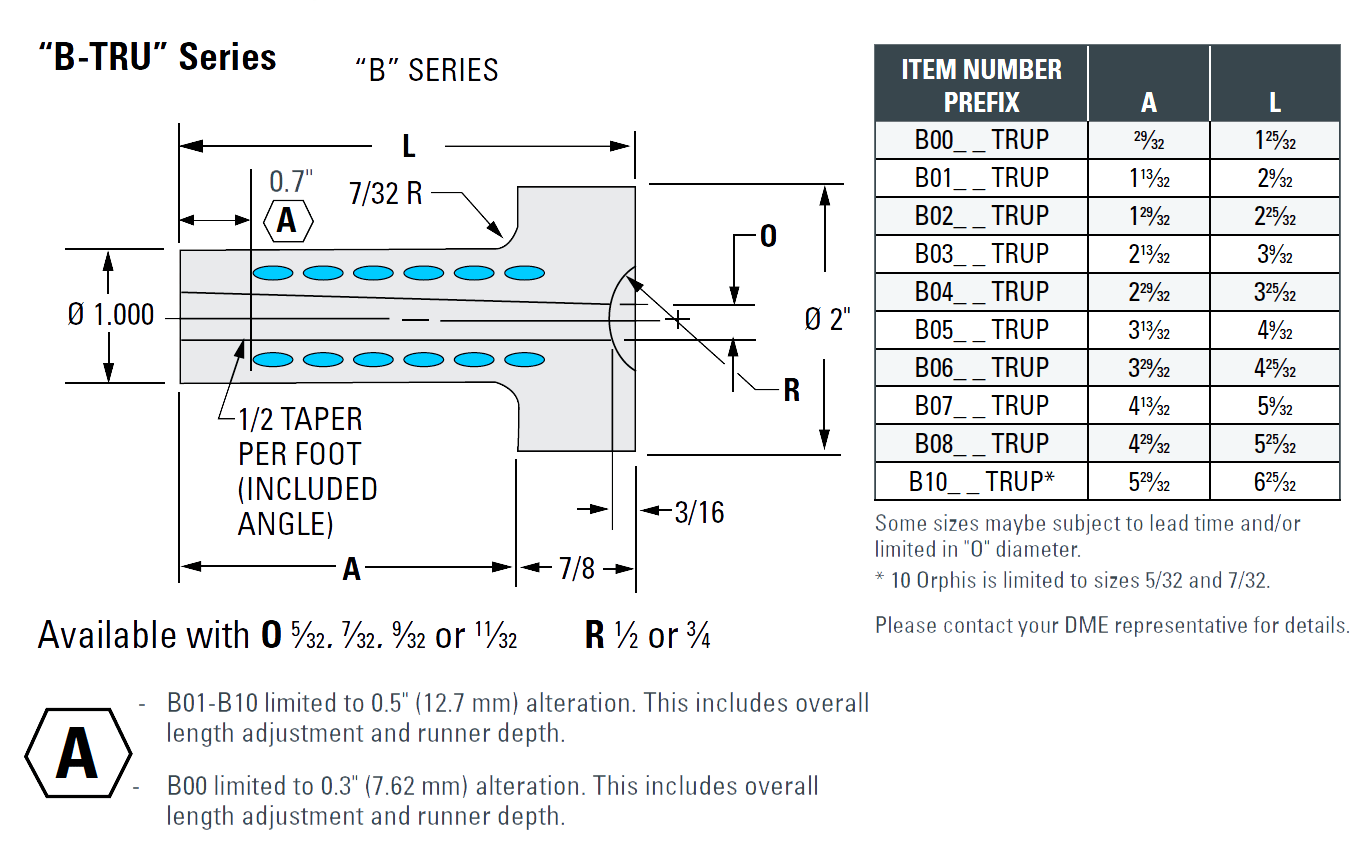

B00TRUP Conformal Cooled Cold Sprues B01TRUP Conformal Cooled Cold Sprues

B02TRUP Conformal Cooled Cold Sprues B03TRUP Conformal Cooled Cold Sprues

B04TRUP Conformal Cooled Cold Sprues B05TRUP Conformal Cooled Cold Sprues

B06TRUP Conformal Cooled Cold Sprues B07TRUP Conformal Cooled Cold Sprues

B08TRUP Conformal Cooled Cold Sprues B10TRUP Conformal Cooled Cold Sprues

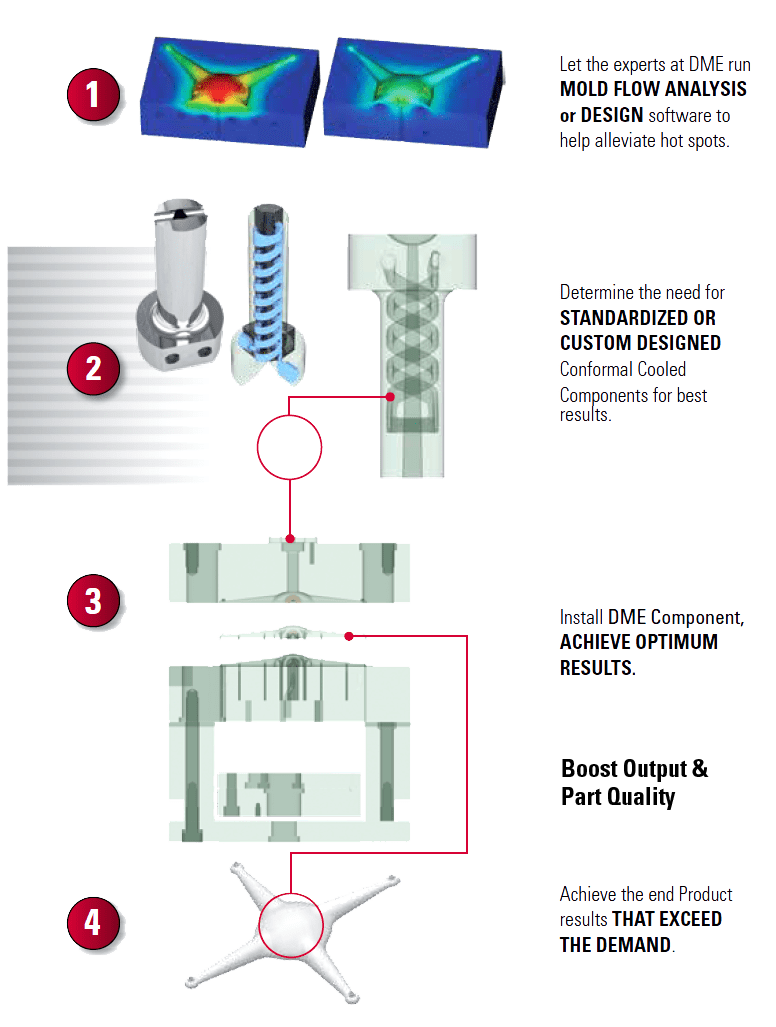

Our Process

To Drive Productivity and Part Quality

Using DME’s latest technology to harness greater control of your tool, you can be a step above competition with superior product while reducing cost, waste and time.

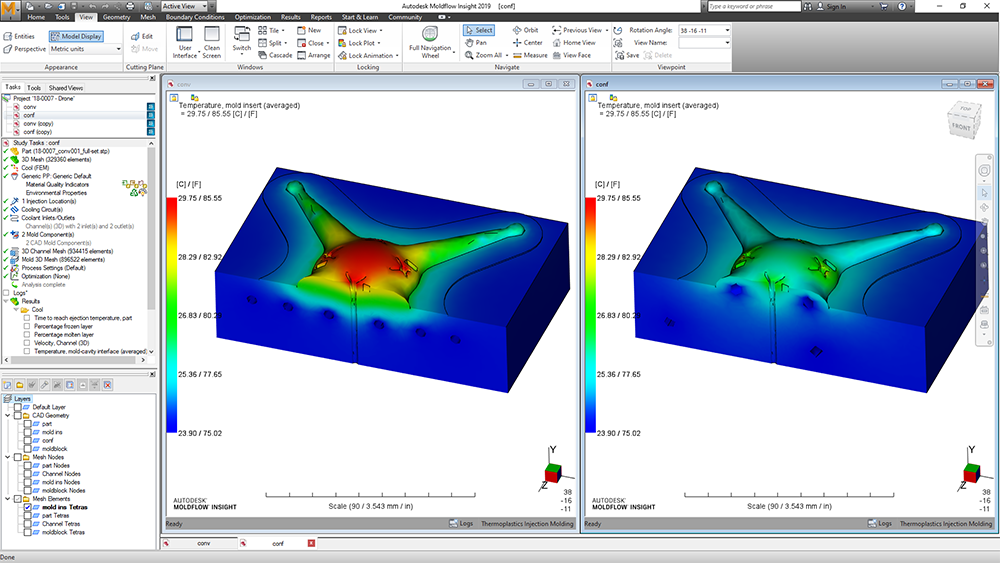

Let The Experts at DME Run Mold Flow Analysis

The skilled team at DME can review an existing project, or a new one coming soon and determine if a conformal cooled gate bushing will provide benefits to your mold.

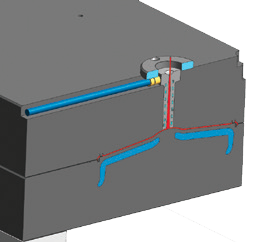

A Cool Upgrade

DME’s cooled sprue bushings are based off our standard B series bushings allowing a very simple exchange to our Cooled Series with minimal tool modification.

Interchangeable with our standard

B-series with minimal tool modification.