DME STEEL

DME has served mold makers worldwide for over seven decades, and we’re still your best choice for mold and die tool steel, precision machined plates, standard and custom mold bases.

- Large On-Site Inventory

- Ready to Ship

- Machined to Your Specifications

Featuring

Benefits of DME Steel

Milling & Finishing Services

DME Steel Grades

Explore the differences in DME Steel Grades. The Standard in Mold Base Steel for over 70 years.

Buy Steel Now

For More Information

We Do Steel

Largest Quantities of Inventoried Tool Steel & Available Machining Services

From the mill to your end product, DME has the right steel for you. We provide value-added machining services to meet your specifications and provide rapid delivery times so your project arrives on time and within budget.

DME not only sells steel, we know steel. Our worldwide steel conversion and machining centers have stocked a diverse array of steel grades and plate sizes all available for quick delivery. Let us put our steel machining experience to work for you.

DME– your one-stop source for tool steel.

Catalog Page

DME Steel is readily available for all markets – more than just for mold industry applications. Our steel’s machinability, uniformity, and consistency make it ideal for a wide variety of uses. Our exclusive supply from the best steel mills allows DME to maintain readily accessible quality stock. This availability means DME can deliver products to you quicker and easier. All DME steel is available in standard and custom widths, lengths, and thicknesses, in RGM or Finish Ground.

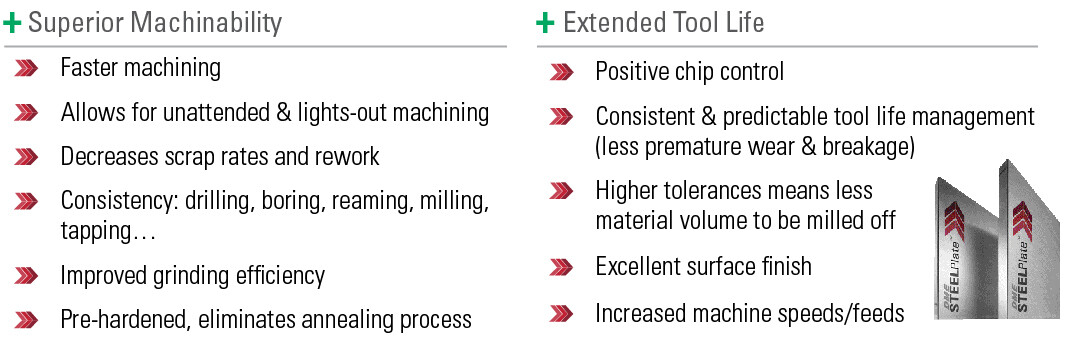

Benefits

Available Steel Plate Finishes

Steel Grades

DME #1 – A36 mild Carbon & 1030 medium Carbon

DME #2 – AISI 4130 medium alloy steel with outstanding properties

DME #3 – P20 modified, preheat treated, highly polishable. A unique formulation, this modified P20 started it all and is still unmatched today.

DME #5 – An H13 with proven long life performance

DME #6 – AISI 420-PH cavity steel, highly polishable

DME #7 – 400 Series stainless (modified)

DME Performance & Quality Delivered

To ensure you only receive the highest & most consistent quality of material, we put DME Steel through its paces before it ever arrives on your doorstep.

In addition to the standard chemical composition and mechanical surface properties, DME machine tests the steel we use. We saw, cut, grind, drill, rough and finish mill DME steel to replicate your operational needs in the world of high-performance machining. Only when it passes DME’s stringent tests do we stamp it with the DME quality mark – then it’s “Machined-4-Quality”.

Look for the “Machine-4-Quality” mark on your next steel order.

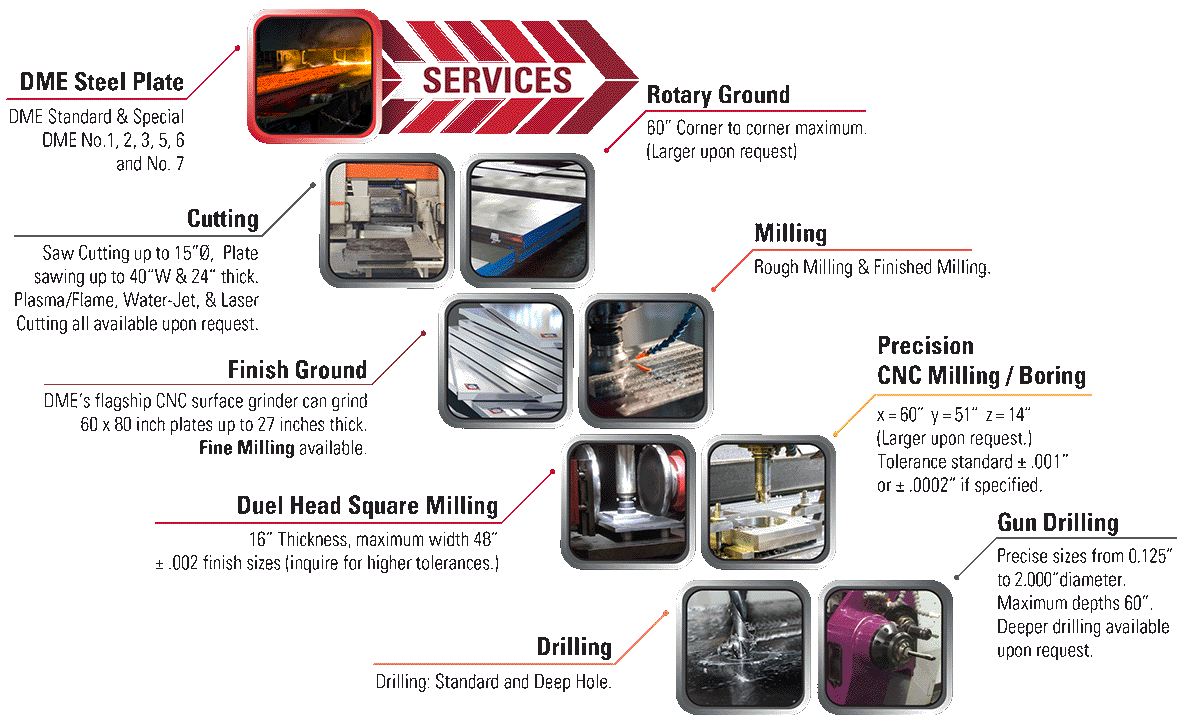

Milling & Finishing Services

With our conveniently located North American Steel Conversion Centers (and many more worldwide), DME provides its customers with an unmatched range of machining services, quality, and delivery speed. DME offers the best in class manufacturing solutions, including CNC machining, grinding, and turning. Our flexible manufacturing services run 24/7, providing you with efficient, cost-effective solutions.

Steel Machining Services Include Cutting, Rotary Ground, Finish Ground, Milling, Dual Head Square Cut, Precision CNC Milling/Boring, Drilling, and Gun-Drilling.

DME Steel Grades

DME #1 Steel

DME No.1 steel is a medium carbon steel that is machinable, has good weldability and good tensile strength. This quality steel is a great value for cost effective mold steel alternatives. Available in rotary ground (RGM) or finished ground (FG), and comes off-the-shelf to you when you need it. DME – ready to support your steel needs today.

Applications

DME No.1 Steel is a quality steel with approximately 25% greater tensile strength than typical low-carbon warehouse steel. It machines easily and is available in both RGM and Finish Ground. Various applications for this steel formulation include but are not limited to:

- Injection Molds

- Extrusion Molds

- Blow Molds

- Other applications such as clamp supports, backers, bolsters, rails, and more.

DME #2 Steel

AISI 4130 Steel

DME Steel No.2 is a vacuum-degasssed CR-MO alloyed steel blend which comes preheated. DME steel has been trusted for over seven decades to give you the quality level you need for a vast array of molding and mold-based applications. Available in rotary ground (RGM) or finished ground (FG); this heat treated mold steel comes off-the-shelf to you when you need it. DME – ready to support your steel needs today.

Applications

DME No.2 Steel is an AISI 4130 type holder block steel is supplied pre-heat treated to 28-34 HRC (271-321 Bhn). A high-strength steel, DME No. 2 is ideal for cavity and core retainer plates, clamping plates, and support plates in molds and dies. Various application for this versatile steel formulation include but are not limited to:

- Injection Molds

- Extrusion Molds• Die Casting Dies

- Blow Molds

- Structural Or Engineered Applications

- Other applications such as supports, backers, bolsters, die holders, rails and more

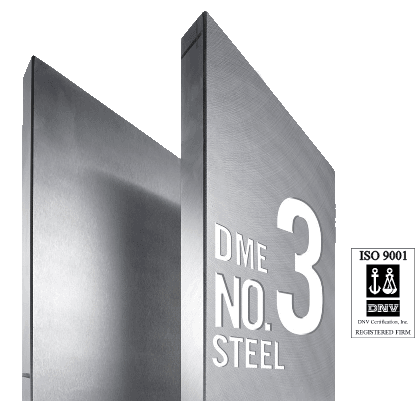

DME #3 Steel

P20 Modified Steel

DME Steel No.3 was formulated for DME in the early 1960’s and has become the industry standard P20 Steel. Trust DME to give you the quality level you need for a vast array of molding and mold-based applications. Available in rotary ground (RGM) or finished ground (FG); this pre-heat treated and tempered mold steel comes off-the-shelf to you when you need it. DME – ready to support your steel needs today.

Applications

DME No.3 Steel is a P-20 (modified) type cavity steel, pre-heat treated to 28-35 HRC (277-332 Bhn). It provides high hardness, exceptional machinability and polishability for both molds and die cast dies. Available in both RGM and Finish Ground. Exceptionally clean and uniform it is comparable to DIN 1.2311 (G40CrMnMo7).

Various application for this versatile steel formulation include but are not limited to:

- Injection Molds

- Extrusion Molds

- Compression Molds

- Blow Molds

- Die Casting Dies

- Structural Or Engineered Applications

- Other applications such as supports, backers, bolsters, die holders, rails, shafts, wear strips and more.

Stainless Steel

DME #7 Steel

AISI 400 Modified Stainless

DME Steel No.7 is an AISI 400 modified stainless steel that has stood the test of time across a variety of uses worldwide. Trusted for decades to give you the quality, durability, and corrosion resistance you need. This stainless provides the excellent machinability, ductility, flatness and weldability you need for a vast array of molding and mold-based applications. Available in rotary ground (RGM) or finished ground (FG) to meet your needs when superior performance is required. When you need the best steel, DME is ready to support your steel needs – today.

Applications

Modified AISI 400 or equivalent series stainless steel for holder block applications. It is supplied pre-hardened to 32-36 HRC (302-340 Bhn) and generally no further heat treatment is required. This stainless steel offers corrosion-resistance and exceptional machinability. Ideal for humid environments, corrosive plastics, clean room or 100% stainless applications.

Various application for this versatile steel formulation include but are not limited to:

- Injection Molds

- Extrusion Molds

- Compression Molds

- Blow Molds

- Die Casting Dies

- Structural Or Engineered Applications

- Other applications