iControl Case Studies

Case Studies Considering Only Cycle Time Reduction

Study #1

120,000 Part production run / 1 cavity = 120,000 IMM cycles

120,000 cycles * cycle time saving 6.6 seconds = 220 hours

220 IMM hours available for other jobs

Average IMM operation cost = $100

Average IMM operator cost / hour = $40

220 Hours saved * $140 / hour = $30,800 savings

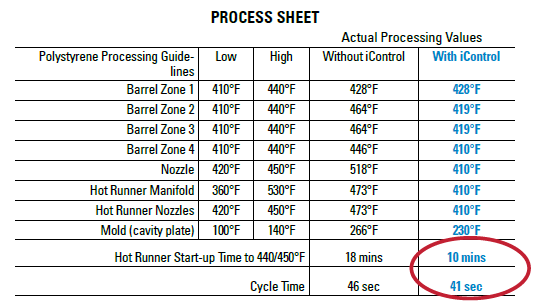

Plus possible emissions savings depending on power generation typeNote: Case study results of iControl installed on a 2 drop hot runner system, processing glass reinforced polypropylene (PP) part (automotive tail lamp housing)

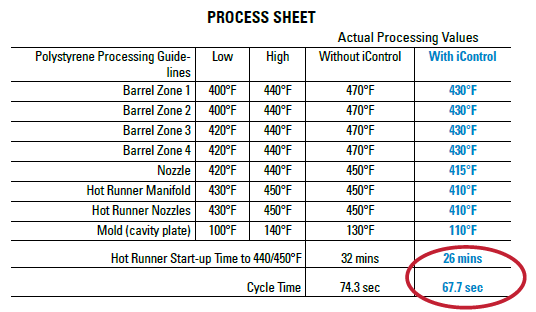

Case Study #2

106,000 Part production run / 1 cavity = 106,000 IMM cycles

106,000 cycles * cycle time saving 5 seconds = 147 hours

147 IMM hours available for other jobs

Average IMM operation cost = $100

Average IMM operator cost / hour = $40

147 Hours saved * $140 / hour = $20,580 savings

Plus possible emissions savings depending on power generation type

Note: Case study results of iControl installed on a 2 drop hot runner system, processing talc filled polypropylene (PP) part (automotive air box)