Scientific Mold Cooling

Scientific mold cooling is when heat is strategically removed from a mold using various scientific processes. This can take many forms, one of the most common ways that scientific mold cooling occurs is when channels are bored into a mold base and fluids, such as water or coolant, can run through them and transfer heat from the mold base to the fluid. This provides a heat sync and accelerates the molding process. Another common method of Scientific Mold Cooling is to use materials that are heat resistant or rapidly lose heat after contact. A great example of this kind of material is copper.

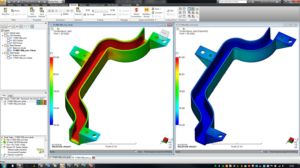

Moldflow Analysis and Conformal Cooling are offered by DME. Moldflow Analysis predicts the heat profile of plastic parts during the molding process and helps to identify hot spots. Conformal Cooling is a technique to get the cooling channels closer to the part surface.

Products That DME Sells That Help With Scientific Cooling

CoolingCare Advanced Cleaning System

DME has a device that cleans out the channels of your mold bases. Our CoolingCare device performs the following functions.

- CLEANING

- PRESSURE / BLOCKAGE / LEAK TESTING

- DIAGNOSTICS

- NEUTRALIZATION & CONSERVATION

- REPORTING

DME CoolingCare helps maintain the efficiency of your cooling channels over the life of the tool. This system saves significant amounts of money with the increased productivity it creates, the downtime it reduces and the costs it reduces. It also extends the lifetime of the tool and reduces the labor costs associated with the tool.