Is your machine running at optimum levels?

You’ve made sure your machine is running at peak performance, but as time passes, degredation of the molds cooling channels can reduce part quality, increase cycle time and overall reduce profitability regardless of how well oiled a machine you’re running.

Proper management, monitoring and maintenance of a molds cooling channels, press feed-throats, chillers and even heat exchangers, can be as easy as adding a tool like DME’s CoolingCare. A true Industry 4.0 tool that works with conventional AND CONFORMAL COOLED channels, the CoolingCare unit can help your mold run a smoothly as your machine.

For more information check out DME’s Cooling Solutions Click Here

And remember to FOLLOW DME on LinkedIn and YouTube for more ways to maximize your productivity!

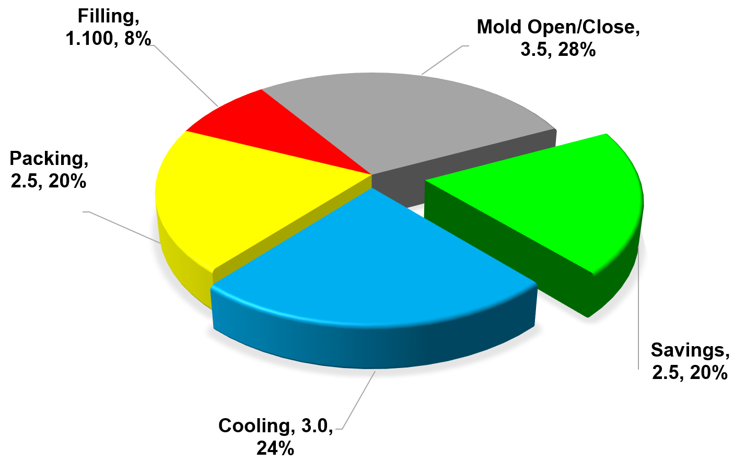

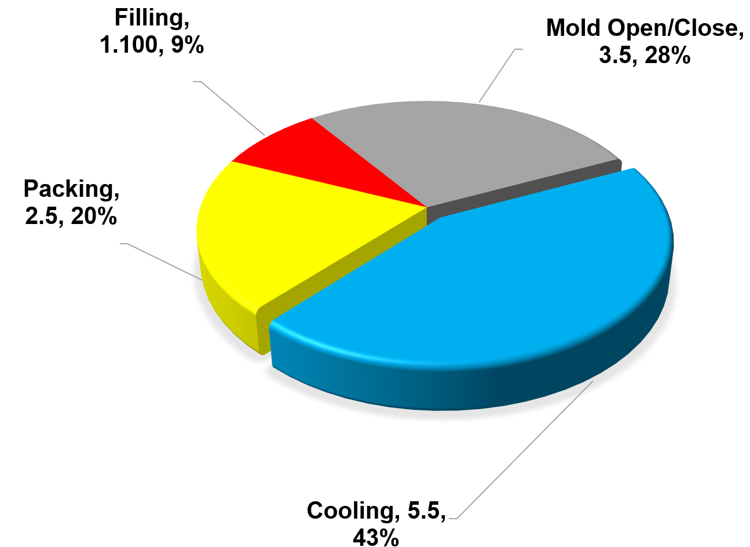

Cooling is a significant percentage of the molding process. See what optimized cooling can do for your part quality and your bottom line.