DME CAD Data

The DME CAD Parts Library is an essential resource to the industry: the most comprehensive tool available to mold designers. At DME we continue to enhance and improve our CAD library based on feedback from our customers.

Featuring:

CAD - Login NOT Required

Access commonly requested CAD data here. Click Here

CAD - Login Required

Access the FULL DME CAD Library. Click Here

CAD Guidelines

Need more information on DME guidelines for CAD? Click Here

DME CAD Resources

The CAD Data You Need

You have two options for accessing CAD data.

Scroll down and check them out.

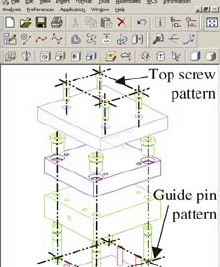

CAD Systems

DME offers our customers an integrated DME mold component CAD library for the following systems:

DME “PARTcommunity”

Global Parts Library

(Login Required)

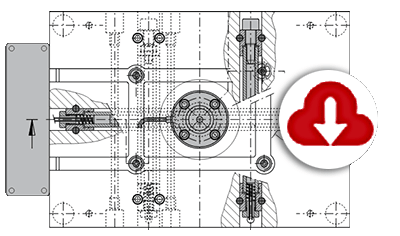

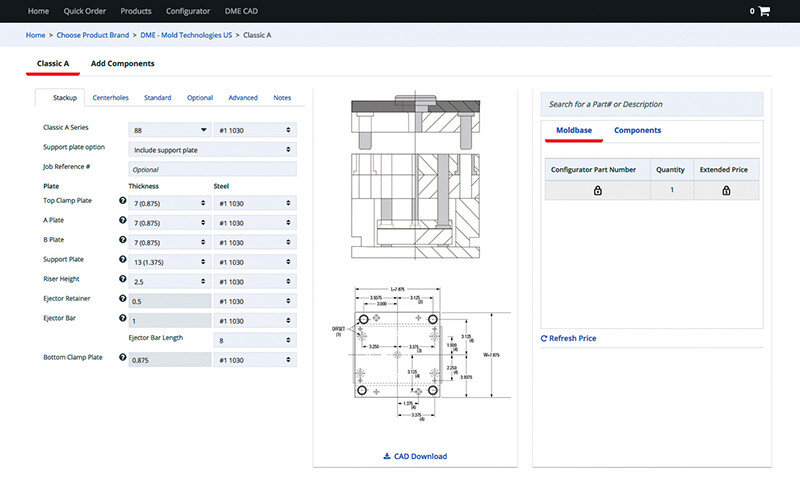

DME PARTcommunity Global Parts Library gives you access to the DME CAD library online. A PARTcommunity login ID is required, which you can acquire online. You can configure products easily, and get models faster with direct download to your computer instead of waiting for an e-mail.

Download CAD files in various application formats from our vast CAD libraries.

Just click the red button above.

DME CAD also available via eSTORE.

Technical Assistance

Need help downloading data? Send an email to [email protected]

Direct CAD Download

(No Login Required)

Access commonly requested DME CAD files by clicking the links below.

For DME Mold Bases, click the links below to go to the DME Configurator for that series of mold base. There you can configure your mold base and download the CAD.

Commonly Requested Mold Base CAD

(Click link below to access configurator):

DME XPress A-Series Mold Base CAD/Configurator

DME XPress B-Series Mold Base CAD/Configurator

DME XPress Stainless Steel A-Series Mold Base CAD/Configurator

Commonly Requested Part CAD

(Click link below to download CAD zip files):

Codipro Swivel Eyebolts & Hoist Rings:

Codipro DSR Double Swivel Hoist Rings

Codipro DSS Double Swivel Hoist Rings

High Temperature Insulator Sheets:

DME Water Manifolds:

platenGUARD Locating Rings:

Friction Pullers:

Thinwall Sleeves:

UniLifter Lifters:

Accualign Lifter CAD:

LifeTime Roller Locks:

Conformal Cooled Cold Sprues:

B00TRUP Conformal Cooled Cold Sprues

B01TRUP Conformal Cooled Cold Sprues

B02TRUP Conformal Cooled Cold Sprues

B03TRUP Conformal Cooled Cold Sprues

B04TRUP Conformal Cooled Cold Sprues

B05TRUP Conformal Cooled Cold Sprues

B06TRUP Conformal Cooled Cold Sprues

B07TRUP Conformal Cooled Cold Sprues

B08TRUP Conformal Cooled Cold Sprues

B10TRUP Conformal Cooled Cold Sprues

EZ Slider – Slide Units:

(angles 0° through 35° included in each file)

EZ-P-L Pneumatic Nitrogen Return with Limit Switch

EZ-S-L Blue Spring Return with Limit Switch

EZ-SG-L Gold Spring Return with Limit Switch

DME CAD Guidelines

At DME we have an assortment of Electronic CAD Communication media which enables customers having all levels of computer expertise to send CAD data.

- The prefered CAD formats include: Parasolid, STEP, DXF and DWG.

- The software DME uses for 3D data is Solidworks.

CAD File Transmission Options

Upload CAD files to our ftp site: https://fileport.milacron.com/form/dme-vendor-upload

If you have more than one file for the same job please zip or compress into one file and copy your files to the incoming folder. Please note: this is a secure folder which does not allow the files to be listed, you will only be able to see your file after the copy process is done and you have refreshed your screen. You cannot create or copy folders to this site, only files. After placing your file on our ftp site, please send an emial to [email protected] with the file name and any special instructions you may require.

General CAD File Guidelines

– Always include your DME account number, company name, contact name and phone number with your CAD data.

– Include instructions as to what to do with your CAD data. For example, is manifold work and/or mold base work to be quoted and/or ordered?

– Please supply fully dimensioned 2D drawings, a 3D model and a complete bill of materials including steel type of plates

– Preferable CAD formats are dwg for 2D drawings, and stp (step), x_t (parasolid) for 3D drawings.

– Clearly identify tolerances you require. In the absence of tolerances, DME will assume our standard tolerances are acceptable

– If your CAD file is complex, provide individual plate details

– If you use layers or levels in your design, please supply a legend that describes information on each layer

– Do not supply cavity or core data unless required by Hot Runner Design, or place it on a layer which is easily removable

– We will be machining from your data, therefore you are responsible for the accuracy of your geometry and all files provided 3D,2D, etc. are consistent with one another

We look forward to supporting you.

Worldwide:

+1.248.398.6000

USA:

+1.800.626.6653

Canada:

+1.800.387.6600

Mexico:

+52.442.713.5666

Europe:

+32.15.215011

Asia:

+86.775.8601.9031

SUPPORT

Customer Support

Order Support

Documentation

Terms of Sale

Return

FAQ

Services

Hot Runner Service & Repair

ProService (CoolingCare)

Application Engineering

Mold Flow Services

Barrel Repair & Resleeving