Collapsible Core

High-quality mold bases and plates available in unlimited configurations to meet every application need.

Benefits For

Designer

Designers gain more freedom and flexibility with pre-engineered DME products, enabling them to devote more time to the creative aspects of mold, die and product design.

Mold & Die Makers

Benefit from additional time to concentrate on cavities and cores to increase productivity by up to 40%.

Molders

Benefit from more quality parts per hour and more profitability with DME production-proven mold construction that outlasts the longest runs.

SHOP DME ONLINE NOW

DME Mold Bases & Plates

Machined For Quality

DME mold bases and plates are manufactured with the highest quality materials on the most advanced, precision equipment in the industry. Pre-engineered assemblies, plates and components provide the economic and technical benefits of interchangeability. Greater metallurgical consistency and more cleanliness in cavity steels mean more reliability for customers.

“DME stepped up to the plate to handle an issue created by a freight carrier. What DME did for us was huge. There are always very good lines of communication between us and DME.

It’s definitely a partnership.”

Steve Newell

Tooling Room Manager

Star Headlight & Lantern Co., Inc.

Dove Tail Collapsible Core

Parts with internal protrusions, dimples, uninterrupted threads and cut-outs can now be economically produced on a high- or low-volume basis.

- For conventional threaded parts, the Collapsible Core could cut your cycle time up to 30% when compared with unscrewing or other complex actuating mechanisms.

- Efficiently mold plastic parts requiring internal threads, undercuts, protrusion or cut-outs.

- Medical, Military, Consumer, Closures, Plumbing, Sporting Goods, Automotive, Shipping Dunnage.

Features & Benefits

- DT Series – Individually Retained Segments 27 size offerings.

- Collapsible Cores offer faster cycle, smaller mold footprint and smaller press daylight requirements than unscrewing.

- Built-In-Cooling channels.

- Collapsible Cores can be Coated.

Specifications

- Core material: A2 Steel. HRC 54-57.

- Center Pins material: D2 Steel. HRC 60-62.

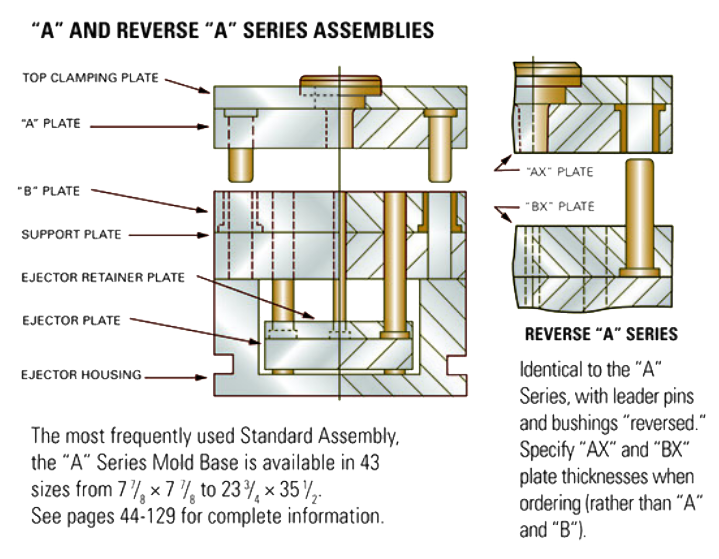

Classic B-Series

DME’s B-Series Mold Bases are a 5 plate design for molds where cavity and core are machined directly into cavity plates.

- B-Series mold bases represents an economy version of the A-Series without sacrificing any quality.

- The B-Series design combines the top clamp plate and the A-plate into the A-Clamping plate. Likewise, a beefed-up B-plate eliminates the need for a support plate on the core side of the mold.

- Available in 43 nominal sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application.

- Other sizes can be ordered as a special.

- Typically called an “open & shut” tool, there is only one parting line where the runner and part(s) are ejected. The cores and cavities are typically inserted into the A and B plates.

- Like all our products, DME’s American “B” series Mold Bases come with your satisfaction 100% guaranteed.

- Available in 43 nominal sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application.

- Other sizes can be ordered as a special.

- High-quality and reliable tolerances mean more time for mold and die makers to concentrate on cavities and cores – thus increasing productivity as much as 40%

- Like all our products, DME’s Mold Bases come with your satisfaction 100% guaranteed.

Features & Benefits

- 5-plate Stack-up includes: A Clamping Plate, B-plate, Support Plate, Ejector Bar, Ejector Retainer Plate and a 3-piece housing.

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.2, No.3, No.7 steel types.

- Allows for components to be added, relocated or omited per your specifications.

Specifications

- In a “B” series mold base the cavity and core are often machined in the A & B plates.

- The cavity or “B” plate is usually thicker and eliminates the need for a support plate.

- Made of high quality, pre-finished mold and die steels that give you more for your money including: metallurgical consistency, more cleanliness in cavity steels, and more reliability.

Quote and Order Information

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

DME XPRESS Series Mold Bases

Superior Steel. Easy to Order. Fast Delivery.

The DME XPress™ Mold Base Series sets the standard for quick delivery with 58,000 combinations ready for same or next day shipment. Configure, Download CAD and Order Online. It’s EASY with the DME Configurator!

For more information on DME’s full line of XPress mold bases click the button below.

MARCH ONLY SPECIAL

Save 15% off list!

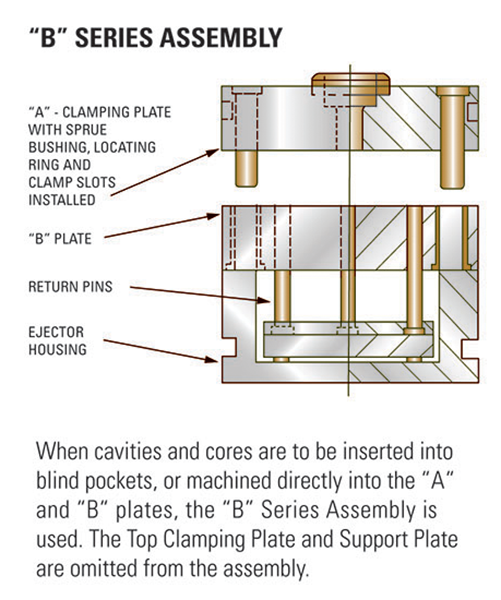

T-Series Mold Base

- T series , or three-plate, mold bases are used for molds that require separation of the part from the runner in the tool.

- T series mold bases consist of an A-clamping plate, X-1 plate, X-2 plate, B-plate, and the ejector assembly and housing.

- T Series mold bases for top runner molds that require two floating plates (X1 runner stripper plate & X2 cavity plate) to remain with stationary half of the assembly.

- The T series operates with two parting lines. The first parting line, which occurs between the X-1 and X-2 plates, separates the part from the gate prior to opening the main parting line. The main parting line then opens and the part is free for ejection.

- Available in 43 nominal sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application. Other sizes can be ordered as a special.

Features & Benefits

- Automatic Degating – in auto mode.

- Separates runner and part.

- Allows central gating – for uniform fill.

Specifications

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.2, No.3, No.7 steel types.

- Machining for Type A, B, C or D Clamp Slots.

- Omission of machining for any component for free.

Quote and Order Information

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

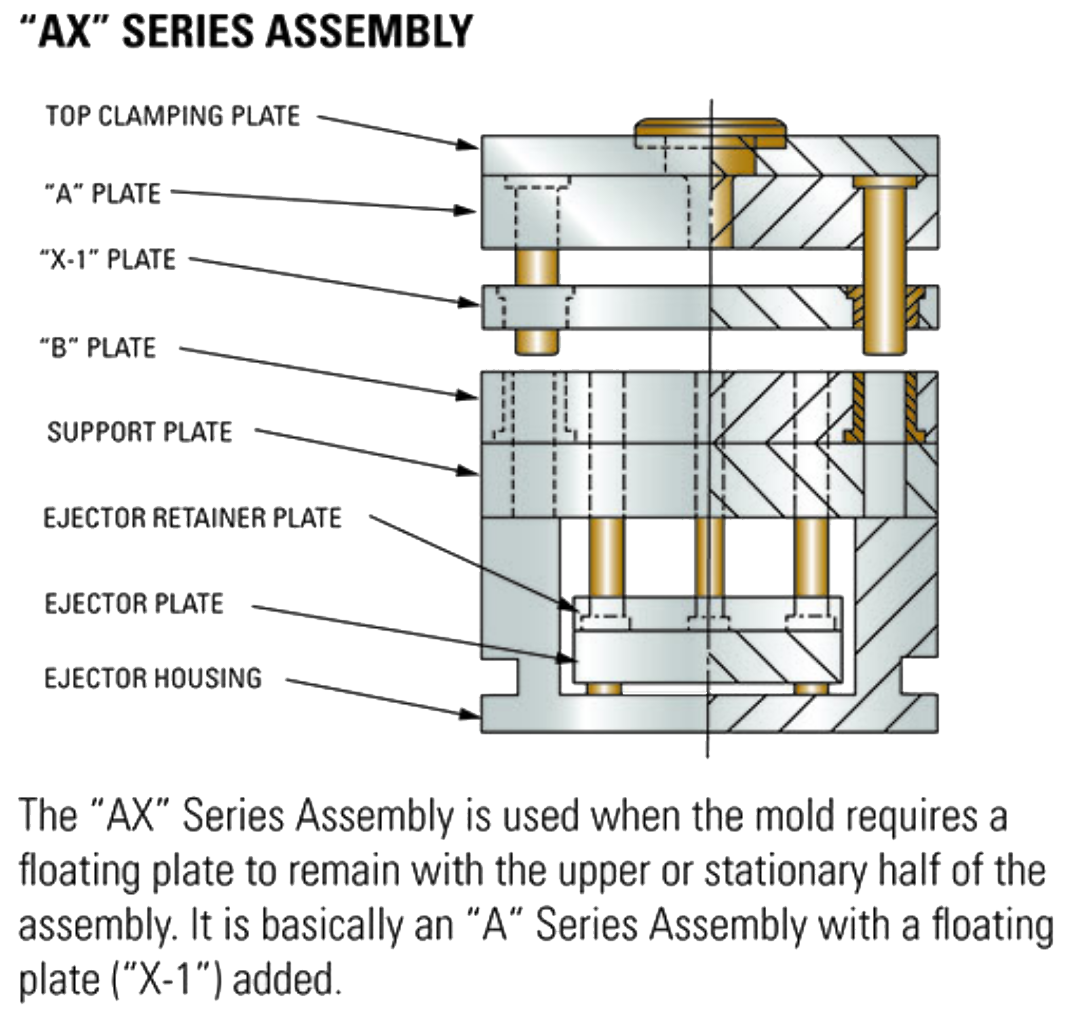

AX-Series Mold Base

DME’s AX-Series Mold Base, is the same as the classic A-Series but with an added floater plate.

- An AX-series mold base is used for parts requiring core detail in the cavity side of the mold.

- When the mold opens, that core detail is pulled so that the part remains on the ejector side of the mold. The AX-series is essentially an A-series mold base with an “-1 plate, located between the A and B-plates but attached to the top half of the mold so that it can pull the part off the core detail.

- Available in 43 nominal sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application. Other sizes can be ordered as a special.

- Like all our products, DME’s AX-series Mold Bases come with your satisfaction 100% guaranteed.

Features & Benefits

- Production-proven construction that outlasts the longest runs, gives molders more quality parts per hour & more profitability.

- Made of high quality, pre-finished mold and die steels that give you more for your money including: metallurgical consistency, more cleanliness in cavity steels, and more reliability.

Specifications

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.2, No.3, No.7 steel types.

Quote and Order Information

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

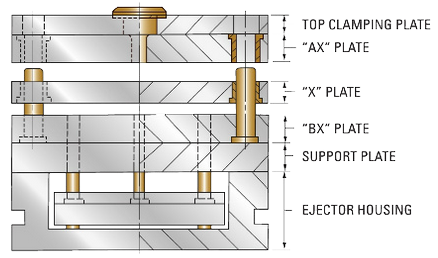

X-Series Mold Base

(5&6 Plate)

DME’s X Series Mold Base is our stripper series with floater plates and reversed leader pins/bushings.

- X -Series, or stripper-plate, mold base sandwiches its stripper (X) plate between the A and B plates and it engages the edge of a part and pushes it off the core.

- The X Series assembly is available with a support plate (6-plate series) or without a support plate (5-plate series). Typically, the X Series is used with round parts like cups, caps, and containers.

- Available in 43 nominal sizes, from 7.875 x 7.875 to 23.75 x 35.5, to match the mold space requirements for your application. Other sizes can be ordered as a special.

- From a name you trust – DME Like all our products, DME’s American “AX” series Mold Bases come with your satisfaction 100% guaranteed.

Features & Benefits

- Has two parting lines – one which allows the runners to de-mold and the other to allow for part removal.

- Automatic Degating – in auto mode.

- Separates runner and part.

- Allows central gating – for uniform fill.

Specifications

- 9 Plate Thicknesses 7/8″ to 5-7/8″.

- No.1, No.2, No.3, No.7 steel types.

Quote and Order Information

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

X-Series 5-Plate

X-Series 6-Plate

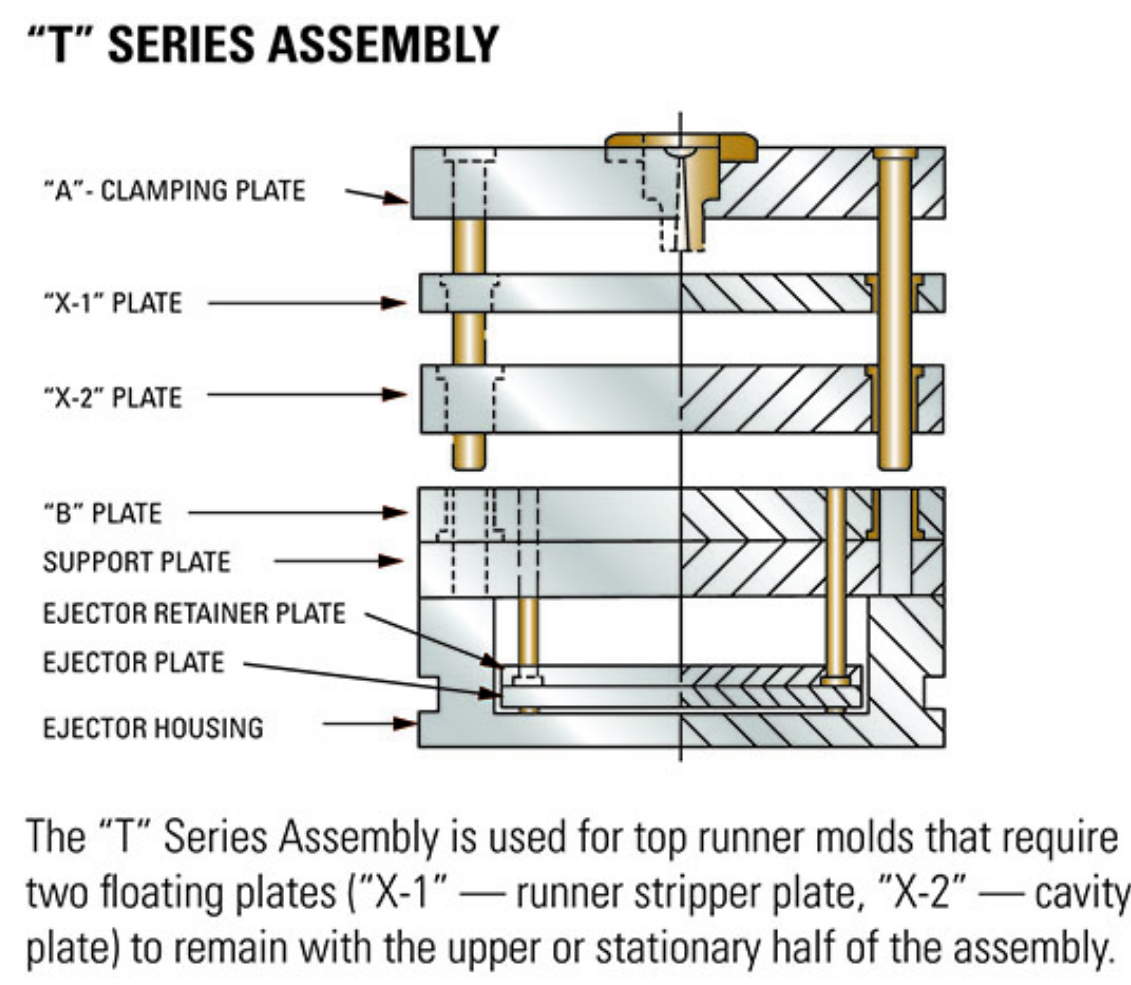

MoldBasics Mold Bases

Need an off-the-shelf mold base solution that ships immediately but offers you the most value?The perfect choice is DME’s value line, Mold Basics™.

The Economical Alternative:

When a projects budget mandates a lower cost, your need is immediate, or for low volume and/or prototype builds. DME’s MoldBasics™ is your choice.

With MoldBasics™ you only pay for the features that you need, but this versatile mold base gives you the ability to add more features later as your project demands.

From a name you trust – DME

Like all our products, DME’s MoldBasics™ line mold bases come with your satisfaction 100% guaranteed.

Features & Benefits

- Cost Effective!

- Designed to grow with your needs.

- Guaranteed DME quality.

Specifications

- Available in DME No.1 steel ( medium carbon, AISI 1045) silicon-killed forging quality steel.

- Available in DME No.2 steel (AISI 4140-type steel) supplied pre-heat treated to 28-34 Rc.

- Sizes from 7.875”x 7.875” up to 15.875”x 23.875”

- Chamfered plates

- 3-piece ejector housing

- Machining for locating ring and screws

- Standard “A” Type clamp slots

Quote and Order Information

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

Worldwide:

+1.248.398.6000

USA:

+1.800.626.6653

Canada:

+1.800.387.6600

Mexico:

+52.442.713.5666

Europe:

+32.15.215011

Asia:

+86.775.8601.9031

SUPPORT

Customer Support

Order Support

Documentation

Terms of Sale

Return

FAQ

Services

Hot Runner Service & Repair

ProService (CoolingCare)

Application Engineering

Mold Flow Services

Barrel Repair & Resleeving