MUD®

Master Unit Die

The MUD® Quick-Change System … proven to deliver increased uptime and reduced costs.

Benefits

Boost OEE Performance

MUD Quick-Change helps improve SMED (single minute exchange of die) boosting production uptime.

Offer Customers Greater Choice

Lower Unit Cost

Low investment and operating cost combined with savings in inventory ensuring lowest possible cost.

SHOP DME ONLINE NOW

MUD® Quick-Change

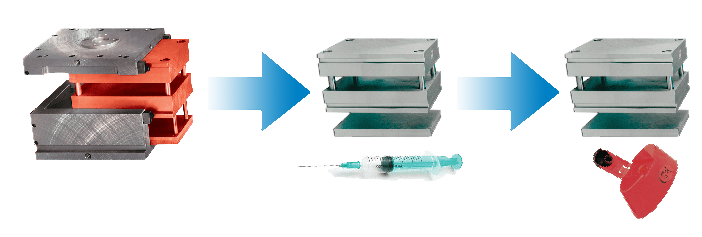

Quick-change frames and companion insert molds for Lean Manufacturing

Mass customization and improved productivity are helping North American companies compete on a global scale. The Master Unit Die Quick-Change (MUD®) System incorporates a static with interchangeable companion insert molds. The system allows the molder to increase productivity, decrease tooling costs and reduce working capital. MUD Quick-Change Systems are becoming a part of the operational strategies of companies who employ lean manufacturing programs further increases uptime and lowering costs. Most changeovers take less than five minutes, require no special equipment and can be made by one person.

“DME stepped up to the plate to handle an issue created by a freight carrier. What DME did for us was huge. There are always very good lines of communication between us and DME.

It’s definitely a partnership.”

Steve Newell

Tooling Room Manager

Star Headlight & Lantern Co., Inc.

The Systems

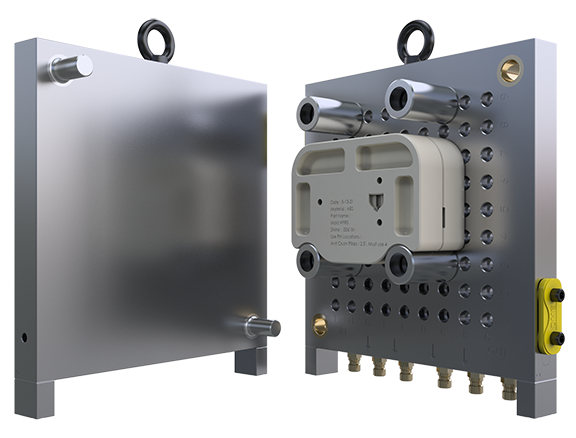

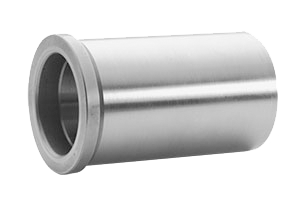

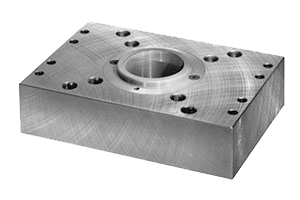

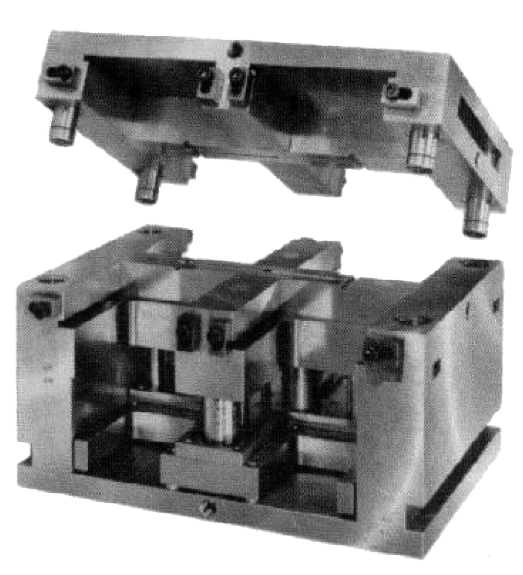

The Master Unit Die Quick-Change (MUD) is an interchangeable modular mold base system. It combines a standard frame and interchangeable A and B insert plates. Different frame types and sizes are available with an unlimited number of complimentary interchangeable mold inserts.

This modular system approach allows the mold maker is work just with the insert plates. The frame remains in the molding machine while the inserts are changed at will.

The beauty of the DME MUD Quick-Change system is its simplicity… like a “razor and blade” the installed frames allowing for easy replacement of the insert with fast delivery and at a value price.

They can either machine the core and cavity directly into the insert or alternatively, via building pockets in which the machined core and cavity inserts can be placed.

The Benefits

The Master Unit Die Quick-Change (MUD) offers a series of compelling benefits:

LOWER TOOLING BUILD COST as you only need to purchase in A& B inserts and not incur the cost of entire mold base.

LOWER MOLDING PROCESSING COSTS from quick mold change (SMED-single minute exchange of die) reducing downtime and lower labor costs as changeovers can be done by a single person maximizing output.

SPEED to market is improved as the frame already pre-exists and all of your machining time can be dedicated to the core and cavity work.

SUSTAINABILITY the only parts of the tool that are discarded are the inserts. The frame can be reused mold after mold.

SUPPLY CHAIN FLEXIBILITY to support just-in-time scheduling

CUSTOMIZATION is greatly enhanced. The low-cost economics combined with the MUD Quick-Change capabilities allows for short run manufacturing. Molders can offer their customers greater variability and lower minimums helping to grow margins and improve cash flow within the supply chain.

The Product Range

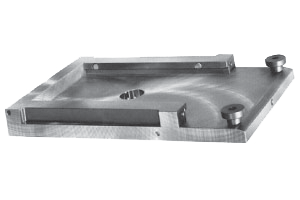

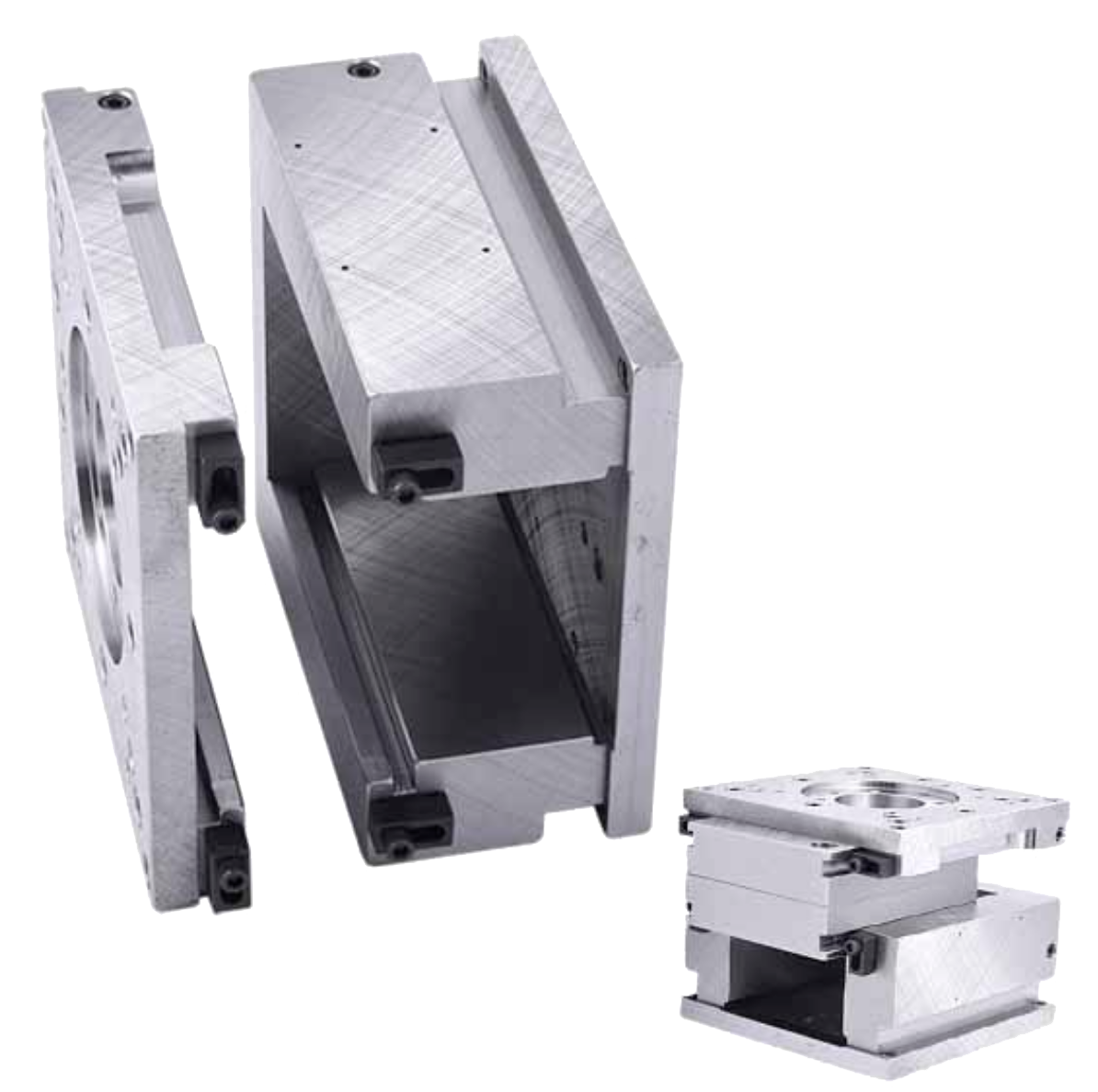

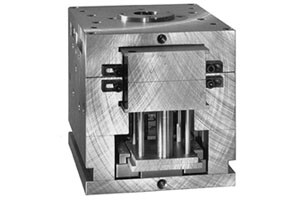

The Master Unit Die Quick-Change (MUD) System consists of a simple frame in which the insert can be placed

There are 4 different frames types depending on the part size and the number of units to produced:

- U-Frame – standard single insert

- H-Frame – standard double insert

- Double H-Frame – standard 4 insert

- E-Frame – side by side double insert

Available Inserts:

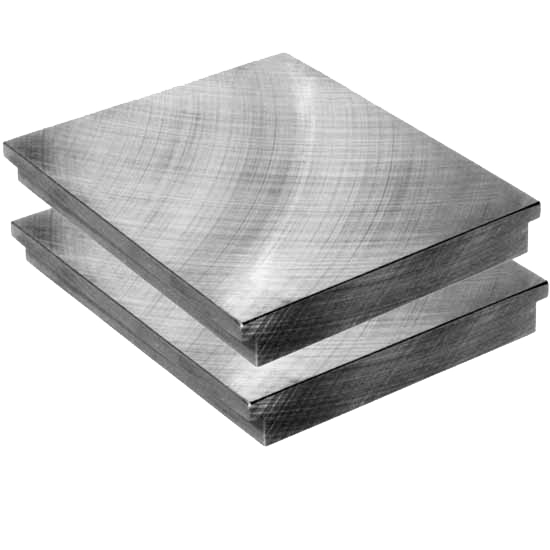

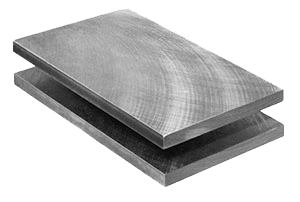

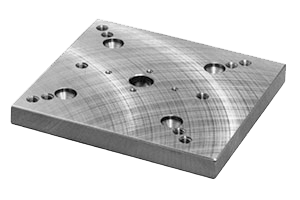

Standard insert molds are the most economical style and are recommended when the additional width of the T-style is not required.

Standard insert molds are available in solid or laminated construction, including three- and four-plate designs.

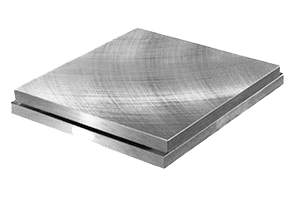

T-style insert molds allow the maximum projected mold area to be used and are available in laminated construction, including three- and four-plate designs. Smaller sizes are available in either solid or laminated construction.

MUD® Quick-Change U-Frames & T-Style

Quick-change frames and companion insert molds accelerate production changeovers and lower tooling costs.

The Master Unit Die Quick-Change (MUD) System is designed to overcome the challenges of increasing productivity and decreasing costs. MUD Quick-Change Systems are more frequently becoming a part of the operational strategies of many companies who employ lean manufacturing programs because MUD systems are proven to deliver increased uptime and reduced costs. Most changeovers take less than five minutes, require no special equipment and can be made by one person.

The MUD quick-change approach to tooling reduces downtime by as much as 75%, and lowers the initial cost of new tooling by as much as 66%. The combined benefits of reduced production downtime, lower labor costs and minimized tooling expense often results in a significant improvement in profit margin.

Features & Benefits

- Two types of companion insert molds available: Standard style (inside frame width) and T-style (outside frame width).

- Due to changeover speed, the machine cylinder is not likely to require purging due to overheating

Specification

- Manufactured with standard pre-hard #2 steel (285-325 Brinell)

- Available in sizes from 05/05 to 18/26

- Includes locating ring & sprue bushing.

- DME offers additional standard sizes which are not listed above – please contact DME Customers Service for more information.

Or please contact DME Customer Service for pricing and availability.

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

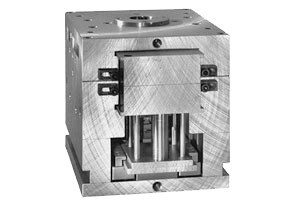

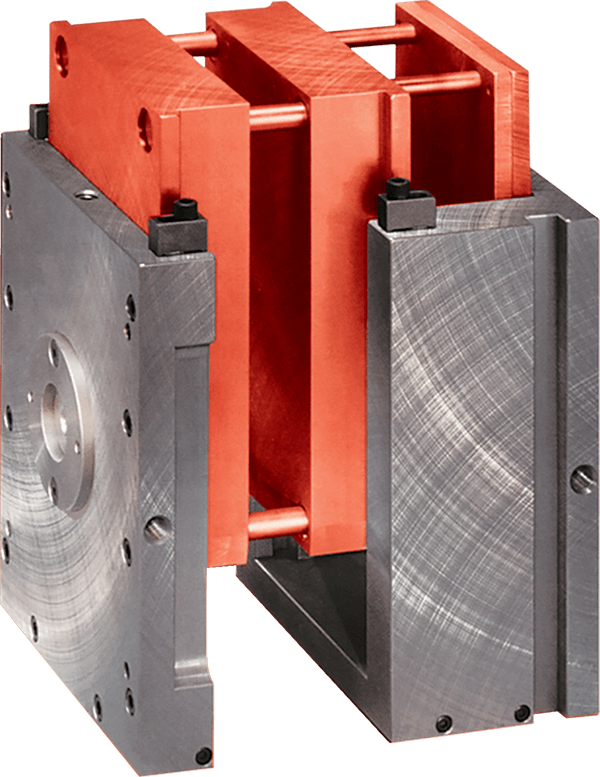

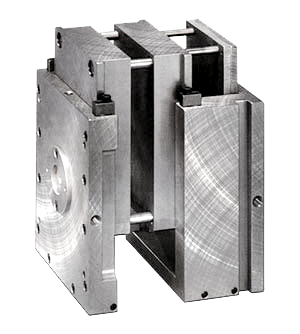

MUD® Quick-Change H and Double H-Frames

This MUD® Quick-Change H-Frame Series features a center runner bar for simultaneous molding with two standard-style companion insert molds. The series offers cost reduction benefits and time-saving advantages similar to the U frame series. It also provides comparable design flexibility.

The two companion insert molds for H-Frames can be changed independently and individually. A dummy insert is supplied for single insert mold production. This results in exceptional versatility for tailoring schedules to virtually all inventory requirements including just-in-time delivery.

H-Frames also offer special advantages for high volume production. Two insert molds permit doubling quantities for each molding cycle. Also, there is virtually no need to interrupt production for maintenance or repair since inexpensive backup insert molds can be quickly installed.

H-Frame: Features & Benefits

- Allows molding with two standard style companion inserts

- One insert can be run by installing a blank insert to block off a section of the frame

- The ejector system can be tied to the master frame with optional interlocking rails

- Applications include both injection and transfer molding

- Can accept hot runner systems

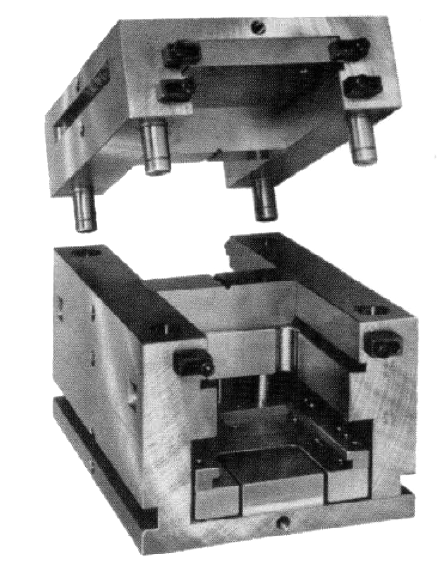

Double H-Frame: Features & Benefits

- The Double H series frame was developed for simultaneous molding of four insert molds

- Blank inserts or runner shut- offs may be used to permit running fewer than four inserts

- The ejector system can be tied to the master frame with optional interlocking rail

- Can accept hot runner systems

MUD H-Frame

MUD Double H-Frame

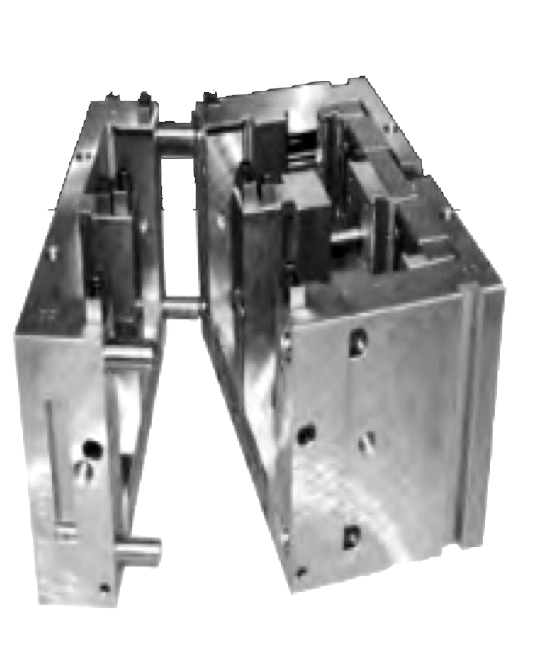

MUD® Quick-Change E-Frames

This MUD® Quick-Change E-Frame Series features a center runner bar for simultaneous molding with two standard-style companion insert molds. The series offers cost reduction benefits and time-saving advantages similar to the U frame series. It also provides comparable design flexibility.

The two companion insert molds for E-Frames can be changed independently and individually. A dummy insert is supplied for single insert mold production. This results in exceptional versatility for tailoring schedules to virtually all inventory requirements including just-in-time delivery.

E-Frames also offer special advantages for high volume production. Two insert molds permit doubling quantities for each molding cycle. Also, there is virtually no need to interrupt production for maintenance or repair since inexpensive backup insert molds can be quickly installed.

E-Frame: Features & Benefits

- For simultaneous molding with two front loading unit molds

- One insert can be run by installing a blank insert to block off a section of the frame

- The ejector system can be tied to the master frame with optional interlocking rails

- Applications include both injection and transfer molding

- Can accept hot runner systems

MUD E-Frame

Quote and Order Information

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

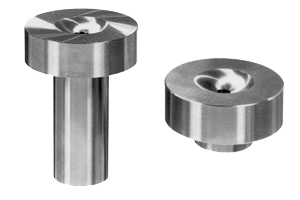

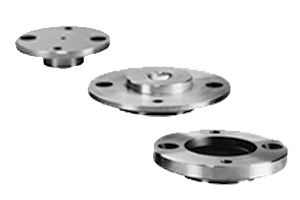

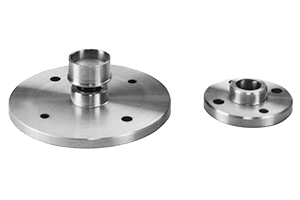

MUD® Inserts

The two MUD companion insert mold styles available with the Quick-Change U-Frame standard style (inside frame width), and T-Style (outside frame width) – offer exceptional design flexibility and versatility.

Standard U-Frame insert molds are the most economical style and are recommended when the additional width of the T-style is not required.

T-Style insert molds allow the maximum projected mold area to be used and are available in laminated construction, including three- and four-plate designs.

Features & Benefits

- Standard insert molds are available in solid or laminated construction, including three- and four-plate designs.

- Smaller sizes are available in either solid or laminated construction.

Specifications

- Companion inserts which are available from stock can be purchased on-line.

Quote and Order Information

Toll-free U.S. – 800-626-6653

Toll-free Canada – 800-387-6600

Worldwide – 248-398-6000

[email protected]

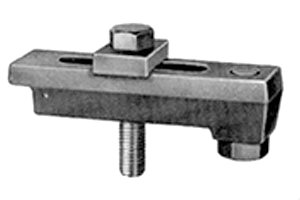

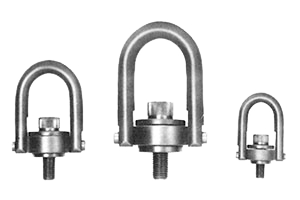

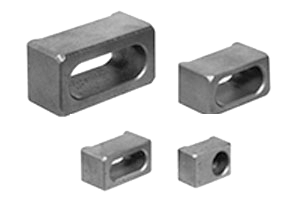

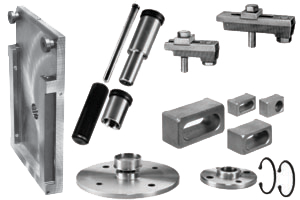

MUD® Components

Every MUD Part- Every Step of the Way!

DME is your complete source for the MUD Components you need to maximize productivity, versatility and maintain an optimum working system.

MUD® Quick-Change frames and companion insert mold series are available with a full range of components. These components permit tailoring MUD frames and insert molds to every injection molding machine up to 500 tons. This makes the cost-saving benefits and time-saving advantages of the Master Unit Die Concept available to virtually every mold maker and plastic molder in the industry. Many companies incorporate MUD Quick-Change Systems as part of their lean manufacturing programs because of the proven value that MUD systems deliver through increased uptime and reduced costs.

Click on a DME MUD Component below to view in our DME eSTORE.

MUD® Quick-Change Options

Quote and Order Information

The wide range of available options enhance the exceptional design versatility of the Master Unit Die Concept. These options can also increase the cost saving benefits and time saving features of this superior approach to injection molding.

The open configuration of the frame permits installation of water lines or hydraulic cylinders in the insert mold. The smaller size and lighter weight of insert molds simplifies machining. These design features also simplify routine maintenance.

MUD systems from DME have a wide breadth of available options. To see the full line of MUD options check out our MUD catalog (click here).

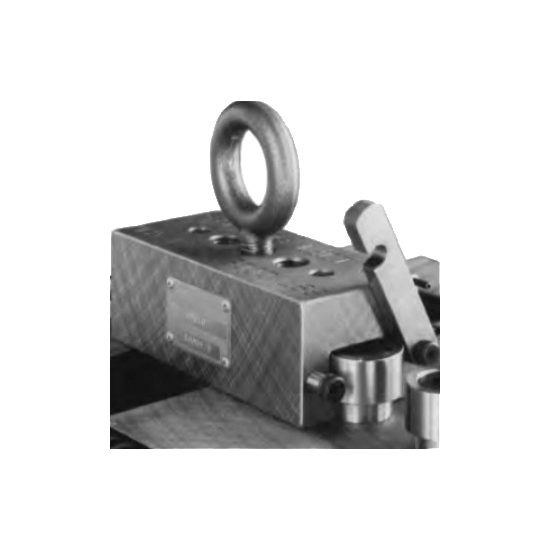

MUD® Quick-Change Mold Base Adapter

Today’s market is more competitive than ever. Consumer trends change quickly yet expectations for delivery are immediate. To compete, a flexible and dynamic world supply chain is required. You need to be able to adapt quickly to your customers demands.So with “Quick Mold Change” being an imperative…

What is the DME Adapter System?

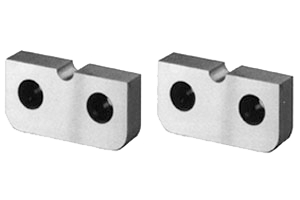

The modular adapter system allows for existing mold bases to be converted into a Quick Change solution save.

Existing mold base make an existing MUD like system.

How the System works?

- The DME adapter frame is installed in the molding machine either by clamping to the press with traditional mold clamps or bolting directly to the press with socket head cap screws and mounting holes (option) installed in the frame.

- Ear plates are attached to the standard mold base with socket head cap screws and dowels.

- Water lines are connected to the integral water manifold.

The Benefits

- Permits quick mold change and instant connecting of the water lines.

- Reduces changeover time dramatically.

MUD® Waterline Purge System

Easy to use and sensibly priced

The MUD Waterline Purge System is ideal for molders who prefer to purge the waterlines before storing their molds. This completely mechanical purge system is specifically engineered for easy operation and virtually no maintenance. The system is installed on the molding machine and becomes an integral part of the waterline system.

This new system allows you to purge your waterlines in 30 seconds or less!

Operation of the MUD Waterline Purge System involves three easy steps. First, turn off the water supply with the two valves. Then, activate the air switch to inject air into the waterlines. After the cooling media has been purged from the system, the mold is ready to be changed. To begin the water flow, just return the valves to the open position. Please note: If you use an enclosed system, the purged cooling media must be drained into a holding container.

Learn more about the MUD Waterline Purge System and the MUD Quick-Change Adapter System with Instant-Connect Waterlines.

The MUD Waterline Purge System is specifically engineered for easy operation and virtually no maintenance.

MUD® Quick-Change Prototype Adapter

RAPID SUCCESS by converting your MUD mold base to a Prototyping Base. Often there is a need for prototypes executed in real production materials, sometimes in low to mid quantities of parts (where production tooling isn’t financially feasible). Your clients often have tight deadlines to meet the need to quickly market test a new product. Adding DME’s Quick-Change Prototype Adapter to your existing MUD Mold System allows you to create fast, high quality parts fit for “real world” use.

Don’t 3D print your parts, 3D print your mold.